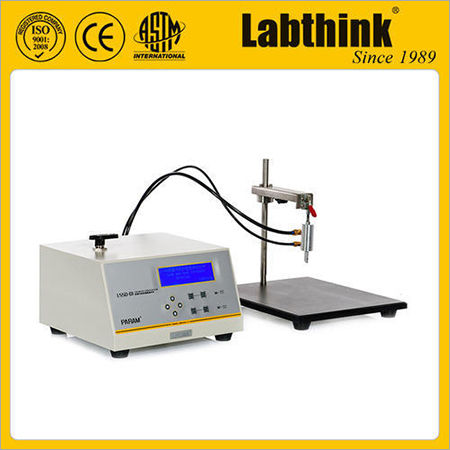

Package Vacuum Leak Detector

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Input Compressed Air

- Output Visual and Audible Leak Status

- Product Type Package Vacuum Leak Detector

- Usage Seal Integrity Testing for Packaging

- Efficiency High Sensitivity (Detects micro leaks up to 10 micron)

- Standard ASTM F2338-09 Compliant

- Insulation Material Acrylic Chamber with Rubber Seal

- Click to View more

X

Package Vacuum Leak Detector Price And Quantity

- 10 Set

- 2000.00 - 20000.00 USD ($)/Set

Package Vacuum Leak Detector Product Specifications

- 350 x 350 x 400 mm

- Package Vacuum Leak Detector

- Transparent/Blue Base

- ASTM F2338-09 Compliant

- Visual and Audible Leak Status

- Compressed Air

- 1% of full scale

- 230V AC, 50 Hz

- Seal Integrity Testing for Packaging

- 230 V AC

- Manual & Digital Options Available

- Approx. 10 kg

- Medium (Chamber: 300 mm Dia x 300 mm H)

- Acrylic Chamber with Rubber Seal

- High Sensitivity (Detects micro leaks up to 10 micron)

Package Vacuum Leak Detector Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Product Details:

| Measurement Range | 0~-90Kpa |

| Display Type | Digital |

| Model | MFY-01 |

Technical Specifications

- Vacuum Degree 0 ~ -90 KPa

- Accuracy 1% FS

- Vacuum Chamber Effective Sizes:270 mm x 210 mm (H) (standard)

- 360 mm x 585 mm (H) (optional):460 mm x 330 mm (H) (optional)

Note: Customization is available for other sizes.

High Sensitivity and Reliable Operation

This vacuum leak detector identifies micro leaks down to 10 microns, ensuring advanced sensitivity in package testing. The durable acrylic chamber and robust rubber seal work together with a dual O-ring system for leak-proof performance. Its inbuilt pressure release valve provides operational safety, while tool-less chamber opening guarantees easy serviceability, making it efficient for frequent quality assurance cycles.

Flexible Test Cycles and Easy Controls

Users benefit from adjustable test cycle durations between 10 and 120 seconds, accommodating various packaging types and testing requirements. The device supports both manual and digital control options, allowing for single-button or toggle switch operation. Leak status updates are instantly communicated through both visual and audible signals, enhancing user confidence and workflow efficiency.

Compliant and Versatile Packaging Integrity Solution

The detector complies with international ASTM F2338-09 standards, ensuring trustworthy results across diverse applications. Compatibility with a wide array of package formatsincluding bottles, pouches, blister packs, and sachetsmakes it versatile for manufacturers, exporters, and retailers. Bench-top mounting and medium chamber size offer practicality for laboratories and industrial settings alike.

FAQs of Package Vacuum Leak Detector:

Q: How does the Package Vacuum Leak Detector identify leaks in packaging?

A: The detector creates a controlled vacuum within the chamber, subjecting the test package to pressure differential. Any breach or micro leak in the packaging causes a drop in pressure, which is detected by the analog or digital gauge and indicated through visual and audible signals.Q: What types of packages can be tested with this vacuum leak detector?

A: It is compatible with various packaging formats, including pouches, blister packs, bottles, and sachets, making it suitable for use in food, pharmaceutical, and industrial packaging sectors.Q: When should seal integrity testing be performed with this device?

A: Seal integrity testing should be carried out during quality control checks, after packaging and sealing processes, or before distribution to ensure product safety and compliance with industry standards.Q: Where can this vacuum leak detector be installed for optimal use?

A: Designed for bench-top mounting, the detector is ideal for laboratory environments, production facilities, or packaging lines requiring convenient and consistent leak testing.Q: What is the process for running a leak test with this equipment?

A: Place the package inside the acrylic chamber, set the desired vacuum level and test cycle time, and initiate the test using either the single button or toggle switch. The device will report leak status both visually and audibly at the end of the cycle.Q: How does the adjustable test cycle benefit users in different settings?

A: With a test cycle adjustable from 10 to 120 seconds, users can tailor the leak detection process to suit a variety of package sizes and test requirements, ensuring thorough evaluation without sacrificing efficiency.Q: What are the key advantages of using this leak detector for packaging applications?

A: Robust construction, high leak detection sensitivity, rapid operation, compliance with ASTM F2338-09, and easy serviceability are some of its primary benefits, offering reliable testing and enhanced product quality assurance for manufacturers and suppliers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Seal Strength Testing Machine' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese