Rigorous WVTR Testing Ensuring Optimal Wound Care Dressing

Product Details:

- Application Wound care dressing, film, textile, hydrocolloid testing

- Test Range 0.011000 g/m/24h

- Gas Pressure 0.01 1 MPa

- Response Time Within 3 seconds

- Frequency 50 Hz

- Features High reproducibility, user-friendly, data storage, programmable

- Resolution 0.01 g/m/24h

- Click to View more

Rigorous WVTR Testing Ensuring Optimal Wound Care Dressing Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Rigorous WVTR Testing Ensuring Optimal Wound Care Dressing Product Specifications

- WVTR (Water Vapor Transmission Rate) assessment

- 0.01 500 mm/min (Adjustable)

- 74 mm (typical)

- Up to 3 simultaneously

- Digital LCD Screen

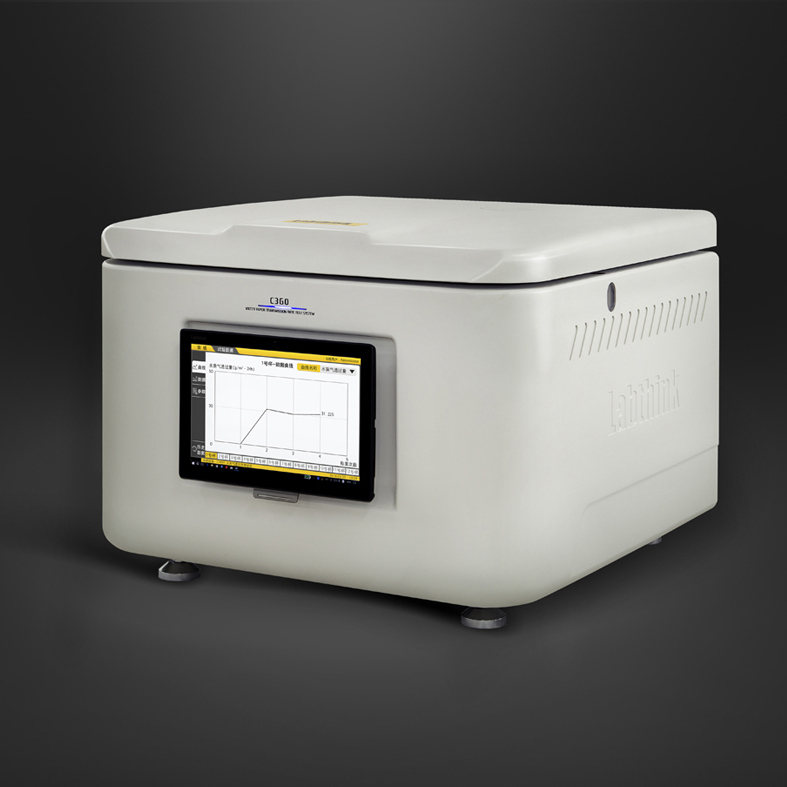

- WVTR Testing Equipment

- RS232, USB

- Approx. 22 kg

- 0.011000 g/m/24h

- 2%

- 220V / 50Hz

- Bench-top

- 30% 90% RH (Adjustable)

- 15C 55C

- 350 mm

- Up to 100 mm

- Up to 150 mm

- 0.011000 g/m/24h

- 0.01 1 MPa

- Within 3 seconds

- Automatic Digital Control

- Wound care dressing, film, textile, hydrocolloid testing

- 3 test chambers

- Automatic

- 6 mm Diameter

- High reproducibility, user-friendly, data storage, programmable

- 50 Hz

- 0.01 g/m/24h

- 220V AC

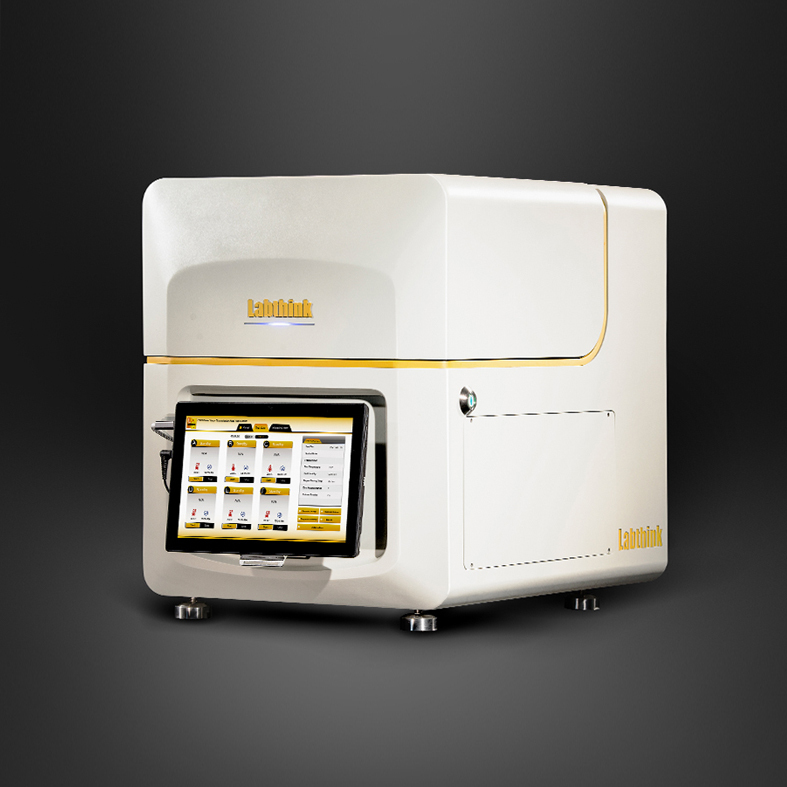

Product Description

High Precision

- Patented test chamber and test dishes with advanced fluid dynamics and thermodynamic designs.

- Labthinks proprietary thermostat technology ensures that the test chamber is precisely temperature controlled and remains stable throughout the test.

- Precise and scientific regulation and calculation of testing conditions.

High Efficiency

- 12 test stations

- Supports test modes of desiccant method and water method

Labor Saving

- Automatic humidity and flow rate controlling.

- Desiccator requires no replacement of inner core.

- High-efficiency water vapor generator.

Simplified Operation

- 12 touch-screen pad powered by WindowsTM 10 operating system

- Fast automatic testing process

- Optional DataShieldTM software and accessories for automatic data management

Product Features

New Generation Test Chamber and Test Dishes

Patented test chamber and test dishes with advanced hydrodynamic and thermodynamic designs ensure the uniform flow rate over the specimen surface, stable temperature and humidity, creating a uniform and stable testing environment. As a result, the test duration is shortened and the test results will be more accurate.

Excellent Testing Abilities of High and Low Barrier Materials

The testing conditions will be regulated precisely in real time, which ensures the high testing accuracy and repeatability of high and low barrier materials.

Automatic Controlling of Temperature, Humidity and Air Velocity

Labthinks proprietary thermostat technology ensures that the test chamber is precisely temperature controlled and remains stable throughout the test.

Air velocity is monitored and regulated in real time.

High-efficiency and mist-free automatic humidity regulator meets the requirements for long-term continuous tests.

It is unnecessary to replace the inner core of the desiccator, which can continuously work for 20,000 hours.

Easy-to-use and High-efficiency System

The automatic test mode, combined with the instrument features, eliminates the need for manual adjustments to quickly obtain accurate results, saving training costs and releasing staff from manual monitoring so that they are available for other tasks.

The professional test mode provides flexible and rich instrument control functions to meet individual scientific research needs.

Unique, optional DataShieldTM system facilitates centralized management of user data. It supports a variety of formats of exported data. Reliable security algorithms are used to prevent data leakage. It supports universal wired and wireless LAN, optional private wireless network and third-party software.

User-oriented Service Concept

Adhering to our user-oriented service concept, Labthink has created a customization system that provides flexible and comprehensive customization services for the accommodation of non-standard specimens and packages.

Test Principle

The test specimen is mounted in the test dish which contains water or desiccant inside. The test dish is placed in the test chamber with stable temperature, humidity and air flow. The water vapor permeates through the specimen and into the dry side. By measuring the weight changes of the test dish periodically, water vapor transmission rate and other parameters can be obtained.

Test Standards

ASTM E96, ASTM D1653, ISO 2528, TAPPI T464, DIN 53122-1, GB/T 1037, GB/T 16928, YBB 00092003-2015

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

Technical Specifications

Table 1: Test Parameters Note1

| Parameter | Model C360H | |

|---|---|---|

| Testing Efficiency | 0.01g/(m2day) 0.5g/(m2day) | >24 hours |

| 0.0006g/(100in2day) 0.0323g/(100in2day) | ||

| 0.5 g/(m2day)5 g/(m2day) | 12 24 hours | |

| 0.0323g/(100in2day) 0.3225g/(100in2day) | ||

| > 5 g/(m2day) | 12 hours | |

| > 0.3225 g/(100in2day) | ||

| Max. Test Range | Water Method | 10000/ni141-12i14g/(m2day) |

| 645/ni141-12i14g/(100in2day) | ||

| Desiccant Method | 1200g/(m2day) per piece | |

| 77g/(100in2day) per piece | ||

| Test Station | 12 | |

| Test Temperature | C | 20 55 0.2 |

| Test Humidity | RH | 10% 90% 1% |

| Additional Functions | DataShieldTM Note2 | Optional |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional | |

Table 2: Technical Specifications

| Specimen Size | I74mm |

|---|---|

| Specimen Thickness | 3mm |

| Test Method | Desiccant Method / Water Method |

| Standard Test Area | 33cm2 |

| Carrier Gas | Compressed Air |

| Drying of Carrier Gas | Long Service-life Desiccator (unnecessary to replace inner core) |

| Humidifying of Carrier Gas | High-efficiency mist-free humidity generator |

| Carrier Gas Pressure | 0.6 MPa |

| Port Size | I6mm PU Tubing |

Note 1: The parameters in the table are measured by professional operator in Labthink laboratory according to relative requirements for laboratory standard conditions.

Note 2: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be purchase as required.

Note 3: The described product features should be in line with Table 1: Test Parameters.

Advanced Compliance & Precision

This WVTR tester meets international standards like ASTM E96 and ISO 2528, making it the ideal solution for industries requiring validated water vapor transmission rate measurements. Its stainless steel build and programmable, automatic digital controls ensure consistency, accuracy within 2%, and ease of calibration, providing confidence in every test result.

Efficient & User-Friendly Operation

The equipment's large digital LCD screen supports multi-language interfaces, allowing effortless navigation and setup. Rapid response times and adjustable test parameters, such as speed, width, and stroke, offer unmatched versatility for various testing needs. Handling up to three specimens simultaneously, it accelerates laboratory throughput and productivity.

Enhanced Safety & Service Support

Built with over-temperature protection, automatic shutdown, and quiet operation (<60 dB), the unit delivers a safe, comfortable user experience. Comprehensive service includes both onsite and remote technical support, ensuring minimal downtime and prompt resolution of any operational queries or maintenance requirements.

FAQ's of Rigorous WVTR Testing Ensuring Optimal Wound Care Dressing:

Q: How does the Rigorous WVTR Testing Equipment ensure accurate and compliant results?

A: This equipment adheres strictly to ASTM E96 and ISO 2528 standards while offering both automatic and manual calibration. With a high accuracy of 2%, precise digital controls, and programmable test parameters, it ensures every measurement is reliable and meets international compliance requirements.Q: What types of samples can be tested, and how many specimens can be analyzed simultaneously?

A: You can use the equipment to test wound care dressings, films, textiles, and hydrocolloid materials. It holds up to three specimens at once through its triple chamber design, enhancing efficiency and maximizing throughput.Q: When should I use the integrated humidification and temperature controls during testing?

A: Integrated humidification and temperature controls allow you to simulate various real-world storage or usage conditions. These features are particularly useful when testing wound care dressings or other materials expected to perform in specific ambient conditions.Q: Where can data from the device be accessed and exported?

A: Test data is stored in the device's built-in memory and can be easily exported via RS232 or USB connectivity to a computer for further analysis or record keeping. The digital LCD screen also provides instant on-site access to results.Q: What is the process for calibration and how often is it required?

A: Calibration can be carried out using automatic or manual methods, both of which are accessible through the digital interface. While frequency depends on usage intensity, it's recommended to calibrate the device regularly or whenever you notice deviations in results.Q: How does the device ensure user safety during operation?

A: Safety is prioritized with features like over-temperature protection and automatic shutdown. The stainless steel construction further ensures durability, and the low ambient noise makes for a comfortable working environment.Q: What are the main benefits of using this WVTR testing equipment in manufacturing or laboratory settings?

A: Key benefits include reliable, reproducible results; high data accuracy; ease of operation via a user-friendly, multi-language interface; flexible sample conditioning; robust data logging; and responsive support through both remote and onsite service options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese