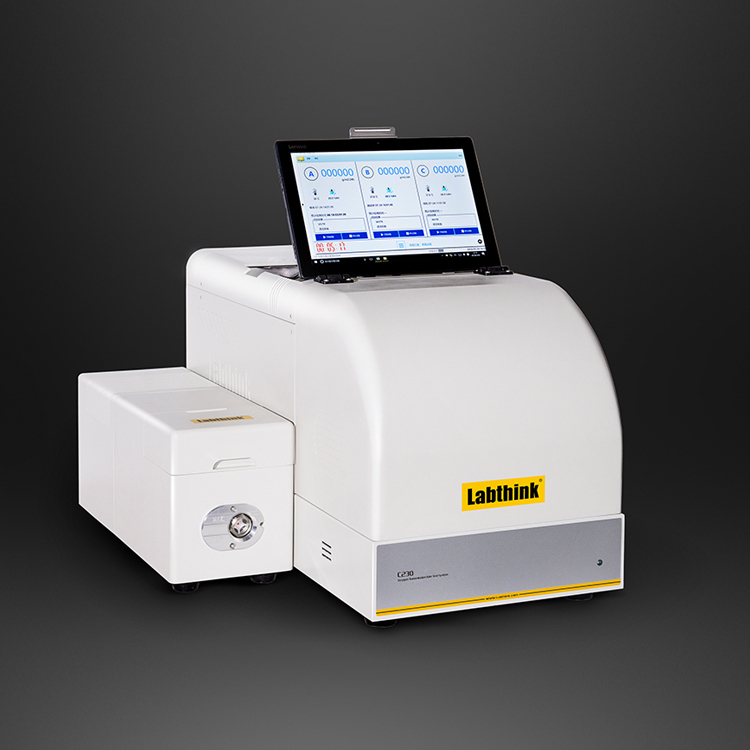

Battery Diaphragm Gas Permeability Analyzer

50000 USD ($)/Set

Product Details:

- Response Time 2 min

- Specimen Size Dia. 25mm, thickness 0.01-3mm

- Operating Voltage 220V AC/50Hz

- Power Supply AC220V, 50Hz

- Port Size 1/8 inch or customized

- Application Battery Diaphragm Gas Permeability Testing

- Humidity 20-90% RH (adjustable)

- Click to View more

X

Battery Diaphragm Gas Permeability Analyzer Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

- 1 Set

Battery Diaphragm Gas Permeability Analyzer Product Specifications

- Gas Permeability Analyzer

- 1-3

- 20-90% RH (adjustable)

- 50-60Hz

- Microcomputer Control

- 0.1MPa~0.6MPa

- 0.01 Barrer

- Automatic

- 220V AC/50Hz

- AC220V, 50Hz

- 2 min

- Laboratory, R&D, Quality Control

- Dia. 25mm, thickness 0.01-3mm

- About 35Kg

- 50mm-100mm

- Battery Diaphragm Gas Permeability Testing

- 1/8 inch or customized

- 1-200mm/min (adjustable)

- 0.01-2000 Barrer

- Digital LCD Touchscreen

- 0.01-2000 Barrer

- 20mm-300mm

- 15C-50C (adjustable)

- 500 mm

- Up to 200mL/min

- RS232/USB

- High Sensitivity, PLC Based, Auto-calibration, Real-Time Monitoring

- 0.5% of reading

- Benchtop

Product Description

Product FeaturesNote1

- The instrument is controlled by computer with automatic test process

- Touch screen, easy to learn and easy to operate

- Imported high precision pressure sensors are used, which guarantees the testing accuracy and repeatability

- Imported pneumatic control system with ultra-low failure rate and extremely long service life, which guarantees the seal performance of the whole system

- Environmental temperature and humidity are monitored and recorded in real time

- 3 equivalent specimens can be tested simultaneously with the average value as test result

- Pressure curves are displayed in real time for observation and analysis of the permeation process

- The system supports unit conversion function to meet users requirements for special test

- Customizations are available for special testing function, specimen size or test pressure

Test Principle

Under certain temperature and humidity, a constant gas differential pressure is generated between the two sides of specimen. The gas transmission rate and other parameters can be obtained by analyzing and calculating pressure changes in the lower pressure side.

Test StandardNote1

ISO 5636, SJT 1071.9, GB/T 36363-2018

ApplicationsNote1

| Basic Applications |

|---|

|

Test the gas permeability of battery diaphragms, breathable films and other relative polymer products. |

Technical SpecificationsNote2

| Specifications | BTY-B3P Gas Permeability Tester |

|---|---|

| Test Range | 10 10,000 s/in2100 mL1.21KPa |

| Pressure Range | 0 20 KPa (customization is available for others) |

| High Pressure Resolution | 0.01 KPa |

| High Pressure Accuracy | 0.05 KPa |

| Low Pressure Resolution | 0.1 Pa |

| Low Pressure Accuracy | 0.3 Pa |

| Specimen Size | 12 mm12 mm |

| Test Area | 0.019 sq.in. (12.56 mm2) Customization available for other test areas |

| Number of Specimens | 3, 2 or 1 |

| Test Gas | O2, N2, CO2 and 99.9% dry gas (outside of supply scope) |

| Gas Supply Pressure | 0.6 Mpa (87 psi) |

| Port Size | I4 mm PU Tubing |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Instrument Dimension | 390 mm (L) 433 mm (W) 410 mm (H) |

| Net Weight | 27 kg |

Configurations

- Standard Configurations

- Instrument, Computer, Professional Software, I4 mm PU Tubing (2.5m)

- Note

- 1. The gas supply port of the instrument is I4 mm PU tubing;

2. Customers need to prepare gas supply.

Note 1: The described product features, applications and test standards should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

High-Precision Measurement

Equipped with electrochemical and thermal conductivity sensors, the analyzer delivers accurate readings with a resolution of 0.01 Barrer. The automatic and manual calibration options ensure reliable results for various gas permeability tests, making it ideal for battery diaphragm analysis in professional settings.

Smart Data Management

With built-in memory capable of storing up to 5000 test datasets and adjustable sampling intervals from 1 second to 60 minutes, users can efficiently archive, retrieve, and manage test results. External communication options, such as Ethernet, WiFi, RS232, and USB, allow seamless integration into existing laboratory data systems.

User-Friendly Operation

Featuring a digital LCD touchscreen, intuitive microcomputer control, and PLC-based operation, the analyzer is easy to operate. It supports both automatic and manual calibration, specimen fitting accessories, and a streamlined testing process for comprehensive applications in laboratory, R&D, or quality assurance environments.

FAQ's of Battery Diaphragm Gas Permeability Analyzer:

Q: How does the Battery Diaphragm Gas Permeability Analyzer improve laboratory testing efficiency?

A: The analyzer integrates high-sensitivity sensors, auto-calibration, and real-time monitoring. Its intuitive touchscreen interface and automated features streamline testing workflows, reduce operator error, and accelerate result generation, making laboratory processes faster and more reliable.Q: What calibration methods are available for this analyzer, and how are they performed?

A: The instrument supports both automatic and manual calibration. Automatic calibration simplifies the process by using preset protocols, while manual calibration allows customization for specific testing needs. Both methods ensure measurement precision and compliance with international standards.Q: When should I use the built-in memory function?

A: Use the built-in memory function to store large quantities of test data (up to 5000 datasets), particularly when conducting continuous or batch testing. This enables easy data organization, retrieval, and export for future reference or analysis.Q: Where can the analyzer be deployed for optimal performance?

A: The analyzer is best suited for controlled laboratory environments, research and development facilities, and quality control departments. Its adjustable temperature and humidity settings allow reliable operation in various environmental conditions.Q: What process does the analyzer use to measure gas permeability in battery diaphragms?

A: The analyzer utilizes a benchtop design to accommodate up to three specimens. Gas permeability is measured by passing a controlled flow of test gas through the sample. The instrument records gas transmission rates using sensors, delivering precise results adjusted for temperature, humidity, and pressure.Q: How does the analyzer benefit manufacturers and researchers?

A: Manufacturers and researchers benefit from its high sensitivity, comprehensive compliance with global standards, and automation. The device increases testing accuracy, saves time with automated operation, and supports data-driven decision-making for product development and quality assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Gas Permeability Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese