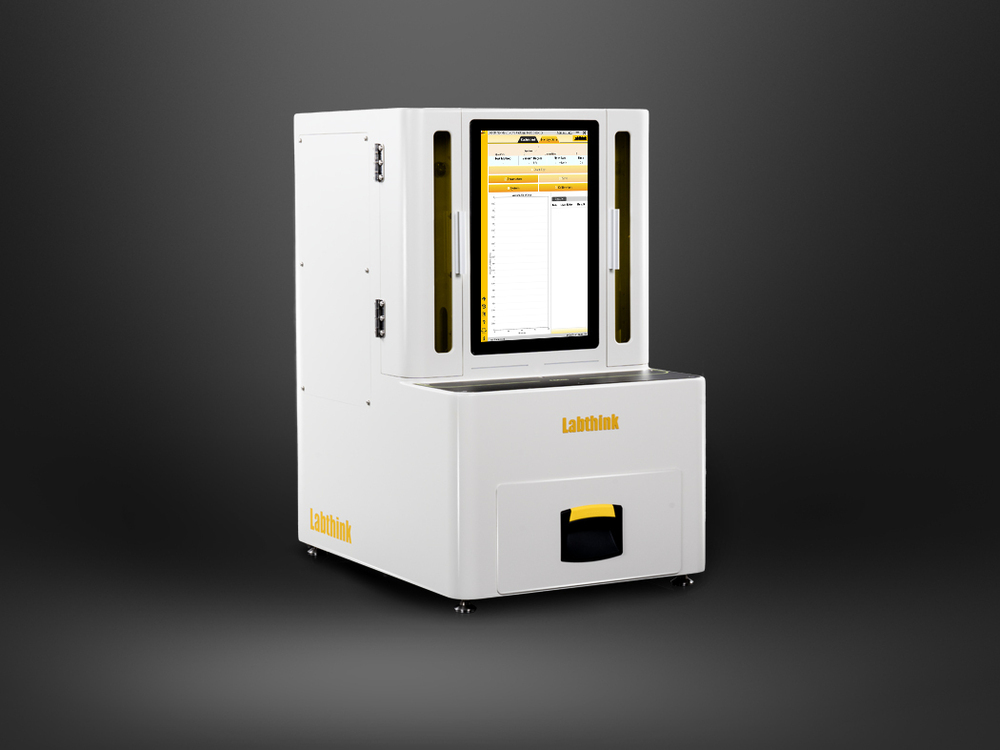

Non-Destructive Packaging Leak Detection Instrument Safeguarding Electronic Components

Product Details:

- Test Material Plastic, Foil, Composite Packaging for Electronic Parts

- Operating Temperature 5C to 40C

- Accuracy 0.001 MPa

- Test Range 0.01 to 1.0 mm leak size detection

- Number of Specimens Single or Multiple (up to 6 samples simultaneously)

- Temperature Tested up to 40C

- Display Digital LCD

- Click to View more

Non-Destructive Packaging Leak Detection Instrument Safeguarding Electronic Components Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Non-Destructive Packaging Leak Detection Instrument Safeguarding Electronic Components Product Specifications

- Medium, accommodates common electronic components packaging

- Industrial Grade Aluminum Alloy

- Non-Destructive Leak Detection Instrument

- Digital LCD

- Dry Air / Nitrogen

- Leak detection and package integrity assurance for electronic components

- 10 mm to 250 mm

- High Sensitivity Pressure Sensor

- Relative Humidity 20% - 80%

- Customized as per package

- AC Mains, 220V, 50/60Hz

- Single or Multiple (up to 6 samples simultaneously)

- Adjustable, 0-1.0 MPa

- Tested up to 40C

- 5C to 40C

- Automatic / Manual

- Plastic, Foil, Composite Packaging for Electronic Parts

- 0.001 MPa

- 220V AC, 50/60 Hz

- 0.01 to 1.0 mm leak size detection

- 2 seconds

- Approx. 15 kg

Product Description

Featuresnote1

Batch Testing

- Equipped with fully-automatic gravity fed sample feeder, which is Labthinks latest scientific and technological achievement that can facilitate continuous testing of 20 to 120 samples.

- A & B dual-channel design can test samples of two different specifications simultaneously.

- The target vacuum degree can be set by the operator to meet testing requirements of different samples.

- Dual methods of vacuum decay and pressure decay provide the flexibility to accommodate various types of package samples.

Precise Data

- Advanced pressure detection technology, using world renowned components for data stability which is not affected by ambient environment.

- Advanced microflow automatic flow control technology that can accurately simulate different sizes of leakage holes without manual adjustment.

- Both the differential pressure transducer and flow meter are traceable to NIST.

- The system can achieve a higher test repeatability of 1um.

Intelligent Control

- 15.6" embedded touch tablet computer with Windows OS.

- New longitudinal interface layout, and easy to use graphic user interface.

- Automatic alarm, automatic capture, automatic collection of unqualified samples.

- The pressure curve is displayed in real time, and the test results are counted automatically.

- Leakage rates are calculated automatically.

- The system is equipped with various sensors as intelligent reminders for safer operation and control.

- Universal printer can be connected for test results output.

- The system features embedded with USB and network ports to facilitate the external access and data transmission of the system, which can be upgraded remotely

Security Compliance

- Verified by compensation and calibration methods.

- The leak tester meets GMP requirements for data traceability and meets the needs of the pharmaceutical industry.

- User operation permission is managed at multiple levels, and the permission content can be configured on demand.

- Electronic signature is designed according to the standard requirements of 21 CFR Part11.

Test Principle

The sample is placed in the sample feeder and automatically delivered into the test cell. The leak rate and other results can be calculated and obtained by analyzing pressure changes measured by the sensor.

Reference Standards

ASTM F2338, YY-T 0681.18, and USP<1207>

Applications

| Basic Applications | Vials | Various vial sealing test. |

| Extended Applications | Ampoule | Various ampoule bottle sealing tests. |

| Cartridge Bottles | Various cartridge bottle sealing tests. | |

| Injection bottles | Various injection bottles sealing test. |

Technical Parameters

Table 1: Test Parameters Note2

| ParameterModel | C690H | |

|---|---|---|

| Testing Range | um(Reference aperture size USP1207) | 3i8igreat leakage |

| Detection Lower Limit | um | 3 |

| Resolution | um | 0.1 |

| Repeatability | um | 1 |

| Pressure Range | kPa | -100i0ii14100 |

| Extended Functions | 21 CFR Part11 | Optional |

| GMP computer system requirements | Optional | |

Table 2: Technical Specifications

| Testing Cell | 1 set for A group and 1 set for B group |

| Sample Feeder | 1 set for A group and 1 set for B group |

| Sample Size | I45 mm80mmNote3 |

| Sample Quantity | 20120 pieces |

| Gas Specifications | Compressed Air (Gas source is provided by the user) |

| Gas Source Pressure | 40.6 PSI / 500 kPa |

| Port Size | I6 mm Polyurethane tube |

| Dimensions | 33.4 H x 19.6 W x 28.7 D (85cm 50cm 73cm) |

| Power | 120VAC10% 60Hz / 220VAC10% 50Hzi14select one from the twoi14 |

| Net weight | 209Lbs (95kg) |

Product Configuration

| Standard Configuration | Mainframe, embedded tablet computer, software, flow meter, European vacuum pump, I6 mm polyurethane tube |

|---|---|

| Customization | Test cell and sample feeder of group A, test cell and sample feeder of group B, negative standard reference sample and positive standard reference sample designed according to sample specifications |

| Optional Parts | GMP computer system requirements, 21 CFR Part11, air compressor, IQ/OQ/PQ documents |

Note 1: The described product characteristics are subject to the specific annotation of the "Technical Parameters" table.

Note 2: The parameters in the table are measured in the Labthink laboratory by professional operators according to the requirements and conditions of the relevant laboratory environmental standards.

Note 3: Group C test cell can be customized for samples beyond the "Sample Size", but the lower detection limit and test range will change according to the sample size, and the actual delivery shall prevail.

Advanced Leak Detection for Electronics

Ensure the integrity of packaging for sensitive electronic components with precise leak detection technology. The instrument uses vacuum decay and pressure drop methods, achieving detection of even minute leaks (0.01 to 1.0 mm) in plastic, foil, or composite electronic packaging. Its high-sensitivity sensor and rapid response time provide accurate and reliable results in QA processes.

Intuitive Interface and Data Security

With a touchscreen interface and multi-language support, the instrument makes operation straightforward for users worldwide. Internal memory and USB export ensure that test data is securely stored and easily retrievable, helping manufacturers comply with industry standards and streamline documentation.

Effortless Installation and Operation

Designed for bench-top or table-top setups, the instrument is suited for a variety of testing environments. Its customizable port and pedestal sizes accommodate most electronic packaging, while automatic and manual modes allow flexible operation. Maintenance is minimal thanks to easy-to-clean industrial grade aluminum construction.

FAQ's of Non-Destructive Packaging Leak Detection Instrument Safeguarding Electronic Components:

Q: How does the non-destructive leak detection instrument work for electronic components packaging?

A: The instrument tests packaging integrity using vacuum decay and pressure drop methods, detecting leaks by measuring pressure changes in the test chamber. This process ensures that packaging for semiconductors, PCBs, and microchips remains air-tight without damaging the contents.Q: What packaging materials and specimen sizes can the device accommodate?

A: It supports plastic, foil, and composite packaging, with specimen sizes ranging from 10 mm to 250 mm. The pedestal size is designed to fit common electronic component packages and is customized to meet specific packaging needs.Q: When should user calibration be performed, and how is it supported?

A: User calibration can be performed whenever necessary to maintain accuracy, especially after extended use or changes in test conditions. The device is factory calibrated but allows for user calibration through its intuitive touchscreen menu for optimal performance.Q: Where can this instrument be installed for optimal performance?

A: This instrument is intended for bench-top or table-top installation in laboratories, production facilities, or packaging QA areas. It requires access to AC mains (220V, 50/60 Hz) and should be operated in environments with temperatures of 5C to 40C and relative humidity from 20% to 80%.Q: What is the process for performing a leak test using the device?

A: Place the specimen into the test chamber, select automatic or manual mode, and initiate the test. The system uses dry air or nitrogen and monitors pressure changes with a high-sensitivity sensor. Visual and audible alarms notify users of detected leaks, and all data is logged internally and is available for export.Q: How does leak detection benefit electronic component manufacturers and exporters?

A: Leak detection ensures the integrity of electronic packaging, reducing the risk of contamination, moisture ingress, and damage during transport and storage. This quality assurance helps manufacturers and exporters comply with CE and RoHS standards, enhancing reliability and reputation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leak and Integrity Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese