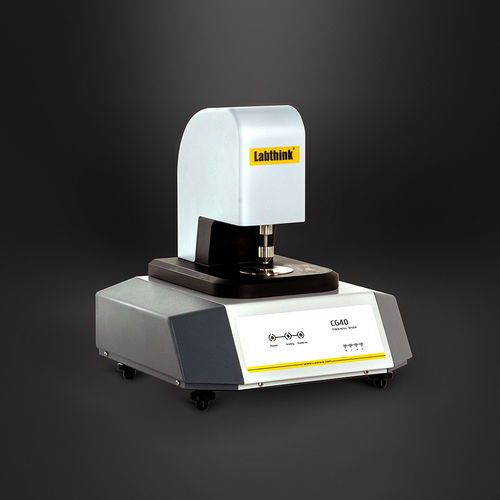

Peel adhesion testing machine for adhesive tape

50000 USD ($)/Set

Product Details:

- Features Automatic graphical report, overload protection, microprocessor control

- Number of Specimens 1 at a time

- Temperature 10C~40C

- Response Time <0.5 seconds

- Frequency 50 Hz

- Accuracy 1% of reading

- Mounting Type Tabletop

- Click to View more

X

Peel adhesion testing machine for adhesive tape Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

- 1 Set

Peel adhesion testing machine for adhesive tape Product Specifications

- 5 kg

- Semi-Automatic

- RS232/USB

- Adhesive Tape Testing

- 500 mm

- Length 100-300 mm x Width 10-100 mm

- 0-50 N

- AC 220V, 50Hz

- 10-100 mm

- 700 mm

- 6 mm

- Adhesive Tape Peel Strength Test

- 0.4~0.7 MPa

- 65 kg

- 220V AC

- Digital LCD

- 300 mm/min

- 0.1~50 N

- 30%~85% RH

- Peel Adhesion Testing Machine

- 0.01 N

- Tabletop

- Digital/Manual

- <0.5 seconds

- 1% of reading

- 50 Hz

- Automatic graphical report, overload protection, microprocessor control

- 1 at a time

- 10C~40C

Product Description

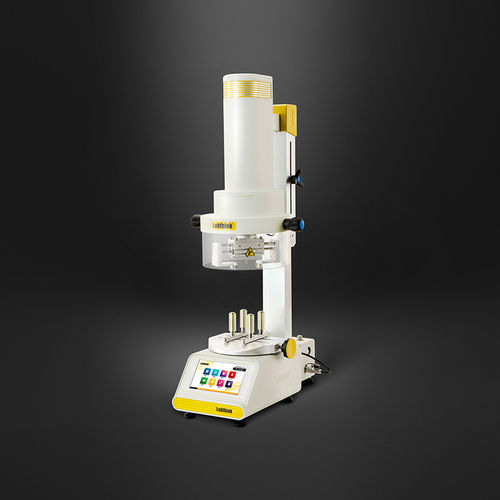

Product FeaturesNote1

Innovative Design of Automatic Lifting of Sled & Upgraded Testing Accuracy and Repeatability

- Two test modes are available i.e. coefficient of friction and peel test

- Innovative automatic lifting of sled ensures accurate still time of the sled and guarantees the high repeatability of coefficient of friction test results

- The sliding plane and the sled are treated by degaussing and remanence detection which effectively reduce the system errors

- Wide range and high-precision of automatic temperature control system to support tests at different temperatures

- Force measuring system is supplied by global well-known supplier, the testing accuracy is higher than 0.5%FS, with better repeatability, multiple test ranges for choice

- Intelligent designs including position restriction, overload protection and auto reset guarantee the safe operation

- The instrument conforms to multiple ISO, ASTM and GB standards

High-end Easy-to-Use Embedded Computer Controlled System

- Large touch screen tablet is easy to view and operate

- Brand new software which is easy to use simplifies the testing operations

- The instrument supports comparative analysis of group of test data, with unit conversion features

- USB ports and net port for data transmission and external connection

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique data security system,separates the test data from the computer to avoid the risks caused by computer virus

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ISO 8295, ISO 8510-2, ASTM D1894, ASTM D4917, ASTM D3330, TAPPI T816, TAPPI T549, GB 10006,GB/T 2790,GB/T 2791,GB/T 2792

Applications

| Basic Applications |

|---|

|

|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

|

Technical SpecificationsNote2

| Specifications | C620H Friction / Peel Tester |

|---|---|

| Test Range | 0 5 N (standard) 0 10 N, 0 30 N, 0 50N, 0 100N (optional) |

| Force Accuracy | Displayed Value 0.5% (10%FS-100%FS) 0.05%FS (0%-10% of the load cell range) |

| Force Resolution | 0.001 N |

| Test Speed | 0 500 mm/min (Any integer within this range can be set) |

| Speed Accuracy | Displayed Value 0.5% (1%100% of maximum speed) |

| Stroke | 10 300 mm |

| Displacement Resolution | 0.01 mm |

| Test Temperature | Room Temperature 100C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 2C (Single point calibration, within effective area of the test platform) |

| Test Platform | 400mm150mm |

| Specimen Thickness | 2 mm |

| Sled | Weight: 200g Size: 63.5mm63.5mm Customization is available |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Instrument Dimension | 635 mm (L) 300 mm (W) 250 mm (H) |

| Net Weight | 25 kg |

Configurations

- Standard Configurations

- Instrument, Tablet, COF Test Fixture, Peel Test Fixture, 200g Sled, Sampling Block

- Optional Parts

- Standard Pressure Roller, Test Plate, Printer, Air Compressor, GMP System, DataShieldTM Note3

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Versatile Peel Angle Testing

The machine offers adjustability for 180 and 90 peel angles, enabling comprehensive performance evaluation of adhesive tapes across different testing standards. This versatility is crucial for laboratories and manufacturers who need to certify multiple tape products for diverse applications. The adjustable clamping and test setup ensures reliable consistency and flexibility regardless of the tape or method used.

Advanced Data Management and Analysis

Built-in digital LCD display and graphical analysis capabilities allow real-time monitoring of the force-displacement curve. Export data swiftly to a PC via RS232 or USB for in-depth analysis using Windows-compatible software. Automatic graphical reports further simplify documentation and aid in quality assurance. These features make the machine ideal for compliance, research, and process improvement purposes.

Robust Construction and Safety Focus

Constructed with heavy-duty mild steel, the device is designed for durability and minimal maintenance. Integrated safety features, such as an emergency stop button and overload protection, secure both the operator and the test specimen. A noise level below 60 dB ensures a safer and more comfortable working environment during prolonged operation.

FAQ's of Peel adhesion testing machine for adhesive tape:

Q: How does the Peel Adhesion Testing Machine measure adhesive tape strength?

A: The machine measures tape strength by gripping the specimen with precision vice clamps and applying a controlled peel at an adjustable angle of 180 or 90. The force required to remove the tape from the substrate is recorded in real-time, displayed digitally, and graphically analyzed to ensure accurate peel strength measurement.Q: What types of data output and analysis are available?

A: Results are displayed on a digital LCD and can be exported via USB or RS232 to a PC. The included analysis software, compatible with Windows, generates real-time force-displacement curves and automatic graphical reports, making it easy to document and further analyze each test.Q: When is it necessary to use emergency stop or overload protection features?

A: Emergency stop and overload protection should be used whenever there is an unexpected malfunction, excessive force application, or imminent risk to the operator or equipment. These features ensure rapid shutdown, prevent equipment damage, and promote operational safety during testing.Q: Where should this machine be installed for optimal performance?

A: The Peel Adhesion Testing Machine is a tabletop unit and should be mounted on a stable, flat work surface in an indoor environment with temperatures between 10C and 40C and humidity levels of 30% to 85% RH. Ensure proximity to a suitable AC 220V power supply and, if needed, a compatible gas line for pressure requirements.Q: What is the process for setting up and conducting a peel test?

A: Set up the specimen using the included cutting template, secure it in the precision vice clamps, select the required peel angle, and set the control mode (digital or manual). Initiate the test; the machine peels the tape at a constant speed of 300 mm/min, logging the force data for analysis. Use the quick-release for easy clamp adjustments between tests.Q: How does this testing machine benefit adhesive tape manufacturers and exporters?

A: The device delivers accurate, repeatable peel strength measurements with efficient data management and robust safety. This ensures quality control, regulatory compliance, improved product development, and trusted certification for adhesive tape products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese