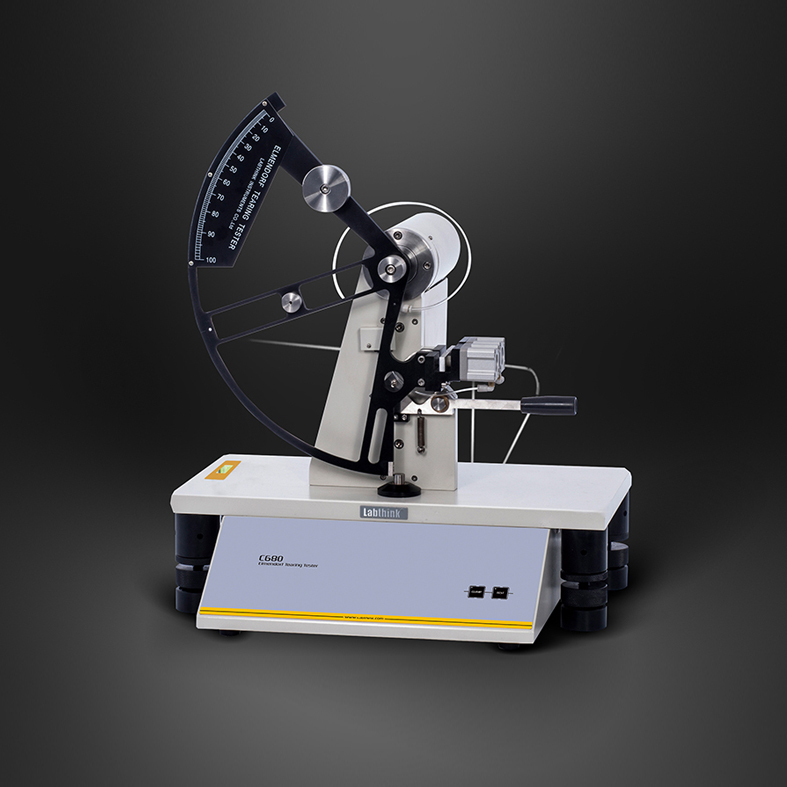

Aluminum plastic composite panel tear strength tester

Product Details:

- Equipment Type Tear Strength Tester

- Frequency 50 Hz

- Automation Grade Semi-automatic

- Application Used for measuring tear strength of aluminum-plastic composite panels and similar materials

- Power Supply AC 220V 10%, 50Hz

- Humidity 20%-80% RH

- Port Size Standard (customizable)

- Click to View more

Aluminum plastic composite panel tear strength tester Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Aluminum plastic composite panel tear strength tester Product Specifications

- Laboratory, Industrial QC

- 0.01 N

- 1 ms

- Room temperature (10-35)

- 600 mm

- 500 N, 1000 N (optional)

- Microcomputer control

- Tear Strength Tester

- 35 kg

- AC 220V 10%, 50Hz

- Standard (customizable)

- 20%-80% RH

- 50 Hz

- Semi-automatic

- Used for measuring tear strength of aluminum-plastic composite panels and similar materials

- AC 220V

- 0.5-0.8 MPa

- 800 mm

- RS232/USB

- 50-500 mm/min (adjustable)

- Test fixtures made from high-hardness alloy steel

- 0-500 N

- Automatic peak hold, overload protection, data output

- 0-500 N

- 0-150 mm

- Bench-top

- (L)100 mm (W)15 mm

- Digital LCD

- 1 per test

- 1%

Product Description

Product Features Notes1

- Computer control, automatic electronic measurement, easy to operate.

- Pneumatic sample clamping and automatic pendulum release can effectively avoid the systematic error caused by human factors.

- Computer assisted adjustment system can ensure the instrument is always in the best test state.

- It can be equipped with multiple groups of pendulum capacity to meet different test requirements.

- Professional software supports the data output of various test units.

- Standard RS232 interface is convenient for external access and data transmission of the system.

Test Principle

Lift the pendulum to a certain height to make it have a certain potential energy; when the pendulum swings freely, it uses its own stored energy to tear the sample; the computer control system calculates the energy consumed in tearing the sample, so as to obtain the force required for tearing the sample.

Reference Standard Notes1

ISO 6383-1-1983, ISO 6383-2-1983, ISO 1974, GB/T 16578.2-2009, GB/T 455, ASTM D1922, ASTM D1424, ASTM D689, TAPPI T414

Test Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

|

|

Technical Parameters Notes2

| Items | Parameters |

|---|---|

| Pendulum Capacity | 200gfa400gfa800gfa1600gfa3200gfa6400gf |

| Air Source Pressure | 0.6 MPa (supplied by user) |

| Air Connection | I 4 mm polyurethane pipe |

| Dimensions | 480 mm (L) 380 mm (W) 560 mm (H) |

| Mainframe Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight of Mainframe | 40kg (200gf basic pendulum) |

Product Configuration Notes1

| Standard configuration | Mainframe, 1 Basic pendulum, 1 calibration weight, professional software, communication cable |

|---|---|

| Options Notes3 | Basic pendulum: 200gf, 1600gf Weight gain: 400gf, 800gf, 3200gf, 6400gf Calibration weights: 200gf, 400gf, 800gf, 1600gf, 3200gf, 6400gf computer |

| Notes | The air source interface of the machine is I 4 mm polyurethane pipe; the air source is provided by the user |

Note 1: The product functions, reference standards and configuration information are subject to the specific marks in the "technical indicators".

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Note 3: "basic pendulum" should select at least one pendulum capacity, "correction weight" should be consistent with the pendulum capacity, and it should be noted when placing an order.

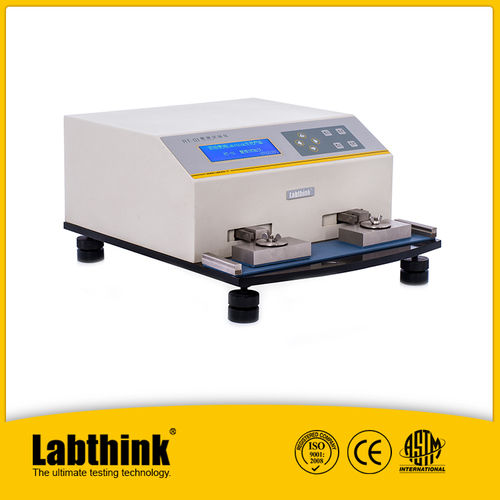

Precision Testing for Composite Materials

Engineered for reliable and accurate measurements, the panel tear strength tester supports rigorous quality control for manufacturers and research laboratories. It handles a wide array of materials such as aluminum-plastic panels and flexible laminates, offering adjustable test speeds and customizable clamps. Automated data analysis and reporting simplify results interpretation, enabling streamlined workflow and improved decision-making for production and research teams.

Comprehensive Software Integration

Users benefit from the included analysis and report generation software, which allows for advanced data handling and seamless export to external devices or computers. The software's multi-language interface ensures accessibility for international users, while automatic peak hold and overload protection features further enhance testing precision. Reports can be quickly printed or exported for traceability and audit compliance.

Safety, Reliability, and Compliance Assured

With built-in emergency stop and overload alarm features, this tester meets industrial safety expectations, safeguarding operators during use. The robust construction, utilizing high-hardness alloy steel test fixtures, ensures durability for intensive laboratory and industrial QC environments. Compliance with GB/T 2790 and ASTM D1922 standards also guarantees trustworthy and comparable results.

FAQ's of Aluminum plastic composite panel tear strength tester:

Q: How does the tear strength tester measure tear resistance in composite panels?

A: The tester utilizes Elmendorf or Trouser type test modes, exerting controlled force on aluminum-plastic panels or laminates to evaluate how much energy is required to tear the sample. The process is digitally regulated for accuracy and the device measures resistance in real time, reporting values with a resolution of 0.01 N.Q: What materials can be tested using this equipment?

A: This device is designed to test aluminum-plastic composite panels, various composite panels, and flexible laminates. Customizable clamps can accommodate specimens with different thicknesses, making it versatile for several material types.Q: When should calibration be performed, and what options are available?

A: Calibration should be conducted before initial use or periodically as required by your quality assurance schedule. The tear strength tester provides both manual and automatic calibration options to ensure precision and reliability.Q: Where can the generated test data be output or exported?

A: Test data can be printed or exported to a PC via the RS232 or USB interface. This allows for easy integration into laboratory information management systems and facilitates report sharing or archiving.Q: What is the typical process for using the tester for a standard tear strength measurement?

A: Begin by inserting the properly sized specimen using the customizable clamps, select the test mode (Elmendorf or Trouser), and adjust the test speed as needed. The microcomputer-controlled system will guide you through the process, and results will be displayed digitally. Users can then generate, print, or export comprehensive reports.Q: How does the tester enhance safety during operation?

A: The tester is equipped with a dedicated emergency stop button and an overload alarm system, providing immediate response to potential operational hazards. These features help protect both the operator and the equipment.Q: What are the main benefits of using this tear strength tester in industrial applications?

A: It provides precise measurements, reliable data output, and adherence to major industry standards. The automation features, included software, and customizable hardware make it ideal for laboratory and industrial quality control tasks, streamlining workflows and supporting compliance efforts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Tearing Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese