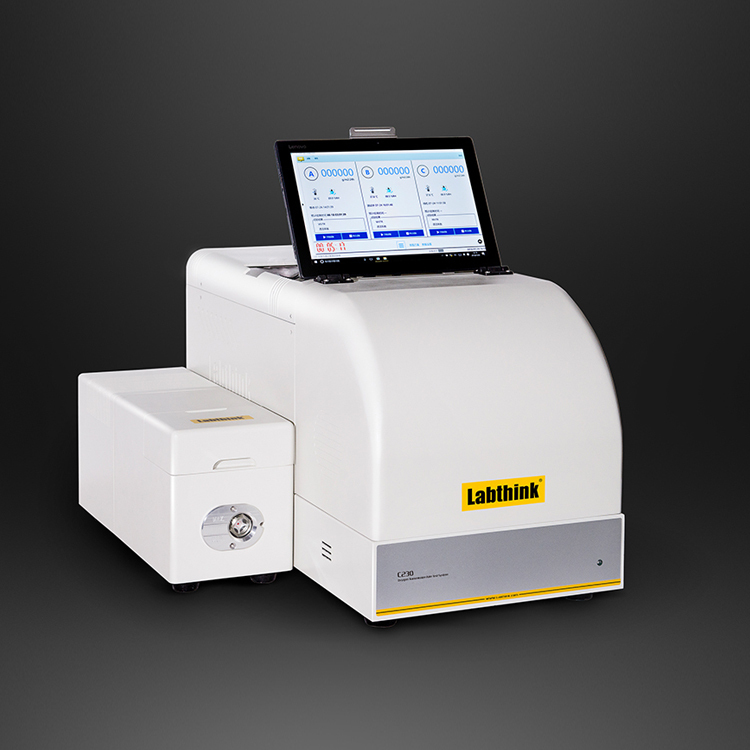

Oxygen Barrier Testing for Protein Powder Packaging

Product Details:

- Max Height 350 mm

- Test Range 0.01 - 10,000 cc/m24h

- Application Protein Powder Packaging Barrier Testing

- Number of Specimens 1 - 3

- Port Size 6 mm

- Mounting Type Tabletop

- Display Type LCD Digital

- Click to View more

Oxygen Barrier Testing for Protein Powder Packaging Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Oxygen Barrier Testing for Protein Powder Packaging Product Specifications

- 350 mm

- Adjustable, 0.1 - 500 mm/min

- 1 - 3

- 6 mm

- Tabletop

- 0.01 - 10,000 cc/m24h

- Protein Powder Packaging Barrier Testing

- 15C - 50C (Controlled)

- Determining Oxygen Permeability in Protein Powder Packaging

- Microprocessor Controlled

- 0 - 300 mm

- LCD Digital

- AC 220V, 50 Hz

- 0.6 MPa (Max)

- 0.01 - 10,000 cc/m24h

- RS232 / USB

- 108 mm x 108 mm

- 10 seconds

- Automatic Data Recording, Calibration, Alarming

- 1% FS

- Oxygen Barrier Testing Instrument

- 0.001 cc/m24h

- 65 kg

- AC 220V

- Automatic

- 30 - 95% RH (Controlled)

- 0 - 300 mm

- 50 Hz

Product Description

Product Features

New Generation Integrated Testing Block

The patented three-cell integrated test block structure using advanced thermodynamics and hydrodynamics analysis greatly improves the temperature, humidity and flow measurement accuracy across the three test cells and supports simultaneous testing of three samples.

Automatic Control of Temperature, Humidity and Flow Rate

The internal temperature and humidity of the instrument are automatically adjusted with temperature and humidity sensors, maintaining the stability of the test specimen environment.

Automatic flow rate control ensures the constant flow during the testing process and minimizes any errors caused by an unstable flow rate.

Easy-to-use and High-efficiency System

The automatic test mode, combined with the instrument features, eliminates the need for manual adjustments to quickly obtain accurate results, saving training costs and releasing staff from manual monitoring so that they are available for other tasks.

The professional test mode provides flexible and rich instrument control functions to meet individual scientific research needs.

Unique, optional DataShieldTM system, meets the requirements for centralized management of user data. It supports a variety of formats of exported data. Reliable security algorithms are used to prevent data leakage. It supports universal wired and wireless LAN, optional private wireless network and third-party software.

User-oriented Service Concept

Adhering to our user-oriented service concept, Labthink has created a customization system that provides flexible and comprehensive customization services for the accommodation of non-standard specimens and packages.

Note 1: The parameters in the table are measured by professional operator in Labthink laboratory according to relative requirements for laboratory standard conditions.

Note 2: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be purchase as required.

Note 3: The described product features should be in line with Table 1: Test Parameters.

Test Principle

The pre-conditioned specimen is mounted between the upper and lower chambers at ambient atmospheric pressure. The upper chamber contains oxygen or air and the lower chamber is slowly purged by a stream of nitrogen. Due to the concentration difference between the two chambers, oxygen molecules permeate through the specimen into the nitrogen side and are taken to the coulometric sensor where proportional electrical signals are generated. The oxygen transmission rate is then obtained by analyzing the signals and calculating the volume of oxygen measured by the sensor. For whole package samples, high purity nitrogen flows inside the package, and oxygen or air flows outside.

Test Standards

ASTM D3985, ASTM F1307, ASTM F1927 (option), GB/T 19789, GB/T 31354, DIN 53380-3, JIS K7126-2-B and YBB 00082003-2015

Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

|

|

|

|

Technical Specifications

Table 1: Test Parameters Note1

| Parameter | Model C230H | |

|---|---|---|

| Test Range | cm3/(m2d) (Standard) | 0.01 200 |

| cc/(100in2day) | 0.0007 12.9 | |

| cm3/(pkgd)(Package) | 0.00005 1 | |

| Resolution | cm3/(m2day) | 0.001 |

| Repeatability | cm3/(m2day) | 0.01 or 2% |

| Test Temperature | C | 10 55 0.2 |

| Test Humidity | RH | O2: 0%, 5% 901%, 100% Carrier Gas: 0%, 5% 902%(optional) |

| Additional Functions | Package Test (3L Max.) | Optional |

| DataShieldTM Note2 | Optional | |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional | |

Table 2: Technical Specifications

| Test Chamber | 3 test chambers |

| Specimen Size | 108 mm X 108 mm |

| Specimen Thickness | 3 mm |

| Standard Test Area | 50 cm2 |

| Carrier Gas | 99.999% High-purity Nitrogen (outside of supply scope) |

| Carrier Gas Pressure | 0.28 MPa/40.6psi |

| Port Size | 1/8 inch metal tubing |

Precision Barrier Assessment for Protein Powder Packs

Engineered to deliver accurate and efficient oxygen permeability results, this instrument ensures your protein powder packaging meets the highest quality and safety standards. Microprocessor control, precise temperature and humidity regulation, and a wide range of test settings enable consistent, repeatable results, empowering producers and suppliers to assure packaging durability and shelf-life.

User-Friendly Operation and Comprehensive Safety Features

With intuitive calibration, automatic data logging, and real-time LCD digital display, users can easily operate and analyze test outcomes. The built-in alarm system notifies of any excess pressure or gas leaks, ensuring laboratory and operator safety throughout each test cycle. Data can conveniently be exported via USB or PC for thorough quality documentation.

FAQs of Oxygen Barrier Testing for Protein Powder Packaging:

Q: How does the Oxygen Barrier Testing Instrument evaluate protein powder packaging?

A: The instrument measures oxygen permeability using Coulometric Sensor Technology, following ASTM D3985 and ISO 15105-2 standards. Sample conditioning for humidity and temperature is applied before testing, and the device provides precise results on oxygen transmission rates within a selectable test cycle.Q: What are the benefits of using this instrument for protein powder packaging?

A: Using this instrument ensures reliable and standardized assessment of oxygen barrier properties, which protects protein powder from oxidation and moisture, thereby maintaining product freshness and extending shelf-life.Q: When should I use this oxygen barrier tester during the packaging process?

A: It is recommended to use the tester during the quality control phase of production, after packaging is complete but before the products are released to the market. Regular testing helps maintain packaging standards and prevent product spoilage.Q: Where can the data from the oxygen barrier tests be accessed and stored?

A: Test results are automatically logged and can be exported directly to a PC via USB or RS232 interface. The instruments memory stores up to 10,000 test records, facilitating ongoing monitoring and quality assurance.Q: What is the process for conducting an oxygen barrier test on protein powder packaging?

A: Prepare and condition the sample at the specified humidity and temperature, place it in the testing chamber, and set test parameters (duration, temperature, etc.). Initiate the cycle and let the instrument automatically measure and record the permeability data.Q: How does the calibration and safety system enhance operation?

A: The calibration interface is user-friendly, enabling quick and accurate setup. Safety is prioritized with alarms for overpressure and gas leaks, making it secure to operate in laboratory environments.Q: Can this equipment accommodate various sample sizes and types of packaging?

A: Yes, the instrument handles specimen sizes up to 108 x 108 mm and is suitable for testing a variety of flexible packaging materials used for protein powders, with controllable test widths, adjustable speeds, and multi-sample capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese