Package Integrity Test Apparatus

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Temperature 5C to 40C

- Resolution 0.1 kPa

- Power Supply 220V, 50Hz, single-phase

- Automation Grade Semi-Automatic

- Application Leak and integrity testing for packaging materials

- Gas Pressure 0 - 150 kPa

- Humidity 20% - 80% RH

- Click to View more

X

Package Integrity Test Apparatus Price And Quantity

- 2000.00 - 20000.00 USD ($)/Set

- 1 Set

Package Integrity Test Apparatus Product Specifications

- Semi-Automatic

- 220V, 50Hz, single-phase

- 5C to 40C

- 0.1 kPa

- 1% FS

- 0 - 100 mm

- Digital LCD display

- Package Integrity Test Apparatus

- Easy-to-use control panel, real-time data display, leak detection, user programmable

- Leak and integrity testing for packaging materials

- 20% - 80% RH

- Microprocessor-based digital control

- 0 - 150 kPa

- 10 - 500 mm/min (adjustable)

- 6 mm / customized

- 300 mm

- Package leak testing, seal integrity checking

- Customized as per package

- Table top

- 50 Hz

- 220V AC

- 1 per test

- 0 - 100 kPa

- <2 seconds

- 450 mm

- 35 kg

- RS232 / USB

- up to 5 L

- 0 - 100 kPa

Package Integrity Test Apparatus Trade Information

- 10 Set Per Week

- 7 Days

Product Description

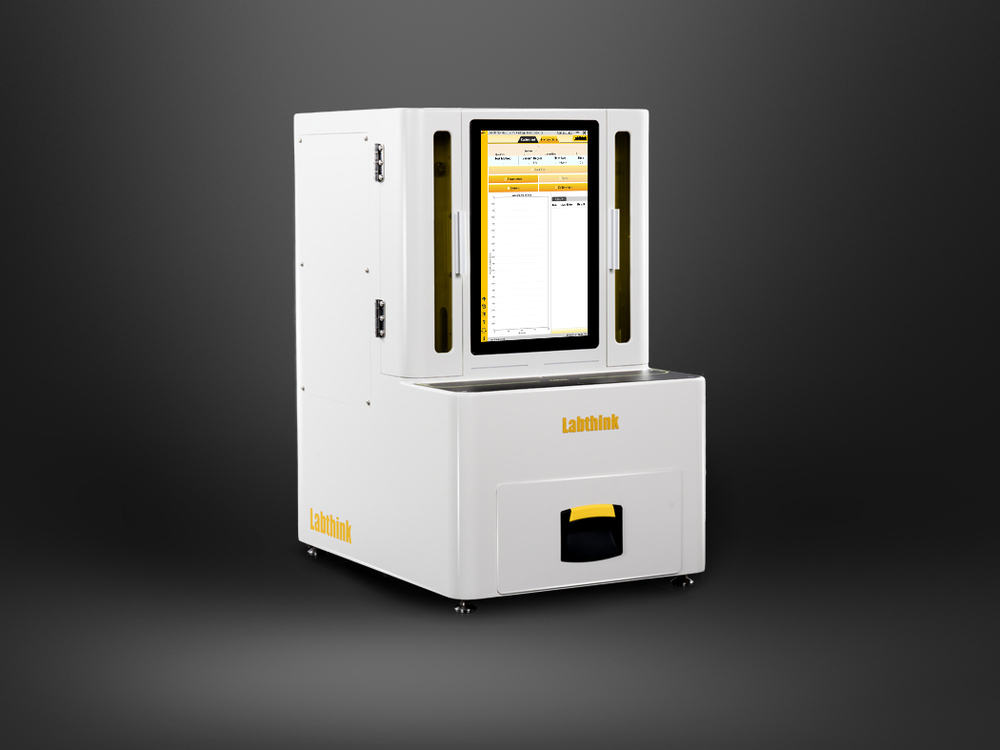

Labthink Package Integrity Test Apparatus

Technical Specifications

- Vacuum Degree 0 ~ -90 KPa

- Accuracy 1% FS

- Vacuum Chamber Effective Sizes 270 mm x 210 mm (H) (standard)

- Instrument Dimension 300 mm (L) x 380 mm (W) x 450 mm (H)

Advanced Leak Detection Technology

The Package Integrity Test Apparatus utilizes sophisticated vacuum generation and microprocessor-based control for highly accurate and repeatable leak detection. Automatic alarms alert users instantly to any leak events, ensuring quality and safety throughout operations. Data stored in the system can be reviewed to enhance traceability and compliance.

Compliance and Safety Assured

Built to meet ASTM F2338 and related standards, this apparatus prioritizes safety with features including automatic pressure relief and an emergency stop. Its robust stainless steel and anodized aluminum construction provides longevity and resistance to corrosion, making it reliable for long-term industrial and laboratory applications.

Versatile, User-Centric Operation

Supporting user-programmable testing up to 60 minutes, the apparatus adapts to various packaging sizes (up to 5 L capacity and 450 mm height). With a digital LCD interface, multi-language options, and an easy-to-use control panel, users achieve seamless operation and data management for both routine and specialized tests.

FAQs of Package Integrity Test Apparatus:

Q: How does the Package Integrity Test Apparatus detect leaks in packaging?

A: This apparatus employs a silent vacuum pump to create differential pressure and uses real-time monitoring with digital controls to detect leaks. Audible and visual alarms automatically signal users if any leakage is discovered, ensuring immediate notification during integrity testing.Q: What materials and packaging sizes are compatible with this equipment?

A: Constructed from stainless steel and anodized aluminum, the test chamber accommodates a variety of package materials and customized specimen sizes, with a capacity of up to 5 liters and a height limit of 450 mm. Specimens can be tailored to meet specific packaging requirements.Q: When is routine service and calibration recommended for the test apparatus?

A: Annual service and calibration are recommended to maintain optimal performance and accuracy. Local support services are available to assist with maintenance, ensuring continued compliance and reliability.Q: Where can the Package Integrity Test Apparatus be installed?

A: The apparatus is designed for tabletop mounting, making it suitable for laboratory environments, production facilities, and quality control departments. Its compact design and low ambient noise (less than 60 dB) allow for flexible placement.Q: What is the process for conducting a package leak test using this apparatus?

A: Users place the specimen in the chamber, set the test parameters using the digital control panel, and commence the test. The apparatus conducts the leak check, monitors pressure, and logs results to its internal storage, with instant warnings if leaks are detected.Q: How does the data storage feature benefit users?

A: Up to 500 test records can be securely stored and reviewed, improving traceability, audit readiness, and workflow efficiency. Data can be accessed via digital display or exported using RS232/USB interfaces for further analysis and reporting.Q: What usage advantages does the Package Integrity Test Apparatus offer for manufacturers and laboratories?

A: It delivers accurate and repeatable leak detection with fast response times, programmable test durations, safety mechanisms, and multi-language support. Its user-friendly interface and automatic alarms enhance productivity and compliance with international standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese