Heat sealing Testers for Plastic Flexible Tubes

50000 USD ($)/Set

Product Details:

- Features Programmable; Data Storage; Easy Calibration

- Gas Pressure 0.6 MPa max

- Resolution 0.01 N

- Max Height 350 mm

- Display Type LCD Digital Display

- Accuracy 1% of reading

- Power Supply 220V, 50Hz

- Click to View more

X

Heat sealing Testers for Plastic Flexible Tubes Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Heat sealing Testers for Plastic Flexible Tubes Product Specifications

- Semi-Automatic

- LCD Digital Display

- 220V, 50Hz

- 1% of reading

- 350 mm

- 0.01 N

- 0.6 MPa max

- 10~100 mm/min adjustable

- Programmable; Data Storage; Easy Calibration

- Custom/Standard

- 6 mm

- Digital microprocessor-based

- Bench-top

- RS232/USB

- up to 10

- Lab Heat Sealing Tester

- 0.5 s

- Quality Control, R&D

- 20%~80% RH

- 300 N

- 200 mm max

- 15C~35C

- 1~300 N

- 50 Hz

- Heat Seal Strength Testing for Plastic Flexible Tubes

- 220 V AC

- 1~300 N

- 0~100 mm adjustable

- 22 kg

Product Description

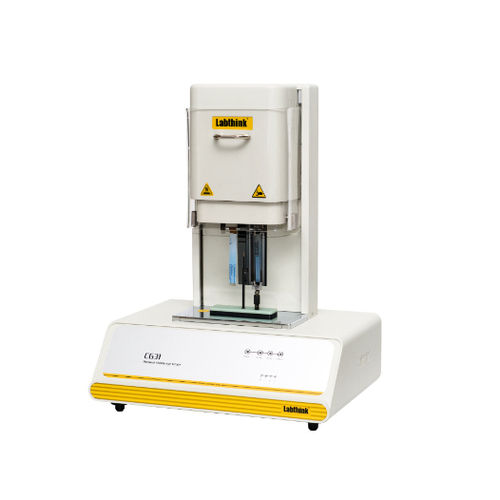

Product FeaturesNote1

- Ten (upper and lower) sealing jaws with metal surfaces to obtain heat sealing parameters that are close to actual parameters

- Digital P.I.D. temperature control technology ensures the preset temperature to be reached rapidly without fluctuations

- Auto constant pressure technology guarantees the stable sealing pressure, requiring no manual adjustment

- Auto leveling technology of sealing jaws ensures uniform sealing performance

- Wide range control of temperature, pressure and time that meet various test conditions

- Manual or pedal switch, as well as anti-scald design provides convenient and safe operating environment

- Professional software supports remote operation for convenient data saving, exporting and printing

Excellent User-oriented, High-efficient and Safe Designs

- The instrument can complete 5 groups of specimen tests at a time, helps the user to obtain heat sealing parameters of the specimens accurately and efficiently.

- The temperature of upper sealing jaws and lower sealing jaws can be controlled separately, which can meet the requirements for different combination of temperatures

- Separated type sealing jaws can be easily replaced

- Manual and pedal switch mode for starting test as well as the anti-scald design ensures the safe operation

High-end and Easy-to-Use Embedded Computer-controlled System

- The instrument is equipped with large size tablet (touch screen), which is easy to operate and observe during the test process

- Brand new software simplifies the testing process.

- The system supports comparison analysis of groups of test data with unit conversion function

- USB ports and internet interface for connecting of external device and data transmission

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique data security system separates the test data from the computer to avoid the risks caused by computer virus

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ASTM F2029, QB/T 2358, YBB 00122003

Applications

| Basic Applications |

|---|

|

|

| Extended Applications |

|

Technical SpecificationsNote2

| Specifications | C630H Heat Seal Tester |

|---|---|

| Sealing Temperature | Room temperature 300C |

| Sealing Pressure | 0.1Mpa 0.7 Mpa (14psi 101psi) |

| Resolution of Pressure | 0.001 MPa |

| Dwell Time | 0.1 999.99 s |

| Resolution of Time | 0.01 s |

| Resolution of Temperature | 0.1C |

| Temperature Fluctuation | 0.2C |

| Temperature Accuracy | 0.5C (single point calibration) |

| Temperature Gradient | 20C |

| Gas Supply Pressure | 0.7 Mpa (101psi) |

| Port Size | 8 mm PU Tubing |

| Sealing Area | 40 mm 10 mm |

| Number of Sealing Jaws | 5 groups of upper and lower sealing jaws with independent temperature control |

| Instrument Dimension | 375mm (L) 360 mm (W) 518mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 55 kg |

Configurations

- Standard Configurations

- Instrument, Tablet, Pedal Switch, High-temperature Welding Cloth, Sample Cutter, 8mm PU Tubing (2m)

- Optional Parts

- High-temperature Welding Cloth, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument is 8 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

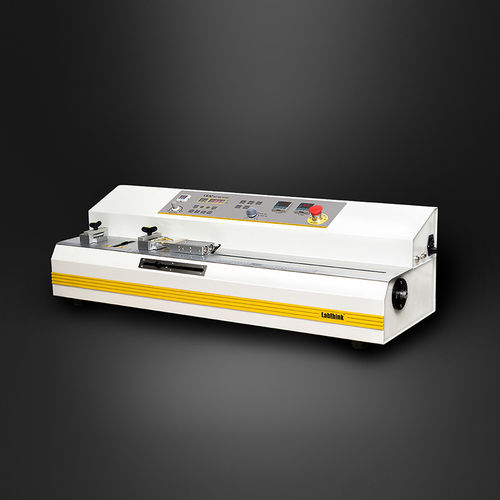

Precision in Heat Seal Testing

This Heat Sealing Tester offers adjustable test speeds (10-100 mm/min) and test widths up to 200 mm, making it suitable for a wide variety of plastic flexible tube applications. Its high accuracy (1% of reading) and fine resolution (0.01 N) ensure that even minor variances in seal strength are detected and quantified. The programmable interface supports both standard and custom specimen sizes, facilitating diverse product assessments.

Advanced Features for Laboratory Excellence

Equipped with digital microprocessor-based controls, this tester enables flexible and reliable operation. Its semi-automatic mode, easy calibration via external weights or auto-calibration, and intuitive LCD digital display simplify use in day-to-day lab activities. Enhanced safety features, temperature control, and direct digital output provide a complete, robust solution for both manufacturers and researchers.

Optimized for Quality Control and R&D

Suitable for exporters, manufacturers, and suppliers, this equipment supports up to 10 specimens per testing cycle, thus increasing laboratory throughput. Automated data handling, USB/RS232 connectivity, and Windows-compatible software support seamless downstream analysis and reporting, delivering time savings and supporting regulatory compliance in packaging industries.

FAQ's of Heat sealing Testers for Plastic Flexible Tubes:

Q: How is the heat sealing strength of plastic flexible tubes tested using this Lab Heat Sealing Tester?

A: The tester evaluates heat seal strength by clamping specimens with self-centering clamps and applying adjustable sealing temperature (room temp to 300C), pressure (0.1-0.7 MPa), and time (0.1~999 s). The sealed sample is then tested for strength using a controlled force (1-300 N test range), with results displayed on the digital LCD and output digitally.Q: What are the benefits of using a digital microprocessor-based control system in this tester?

A: Digital microprocessor-based control ensures precise adjustment and repeatability of test parameters such as sealing time, temperature, and pressure. This technology allows for programmable operation, automated data capture, and real-time monitoring, leading to more consistent and accurate results.Q: When should a manufacturer use this heat sealing tester in their workflow?

A: The tester is best utilized during the quality control stages of the manufacturing process and for research and development activities. It helps ensure the heat seals of plastic tubes meet specific strength requirements dictated by ASTM F88 and ISO 11607 standards before the products reach the market.Q: Where can the test results be accessed and exported from the Heat Sealing Tester?

A: Test results can be viewed on the onboard LCD digital display, printed directly using the digital print output, or exported via RS232/USB interfaces for analysis on compatible Windows software. Data can also be stored onboard or exported via USB for further documentation and reporting.Q: What is the calibration process for this equipment, and how often should it be performed?

A: Calibration is straightforward and can be performed using external weights or the automatic calibration function. The recommended frequency depends on usage intensity and internal quality assurance protocols, but regular calibration-at least annually or before critical testing sessions-ensures ongoing measurement accuracy.Q: How do safety and environmental features enhance the operation of this tester?

A: The tester includes overload protection, emergency stop, and temperature control functions to safeguard users and maintain optimal testing environments. It operates reliably with ambient temperatures between 15C and 35C and relative humidity from 20%-80% RH, ensuring consistent performance regardless of laboratory conditions.Q: What makes this equipment suitable for high-throughput laboratory operations?

A: Its ability to test up to 10 specimens at once, programmable test cycles, self-centering clamps, rapid response time (0.5 s), and efficient data management features together enable laboratories and QA teams to handle large testing volumes quickly and accurately.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese