Testing for Heat-Shrink Tubing for Automotive Applications

Product Details:

- Automation Grade Semi-automatic

- Frequency 50Hz

- Temperature 10C~40C

- Humidity 20%-90% RH

- Gas Pressure 0.4~0.8 MPa

- Measuring Range 0 to 500 N

- Application Automotive Wire Harness, Insulation Testing

- Click to View more

Testing for Heat-Shrink Tubing for Automotive Applications Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Testing for Heat-Shrink Tubing for Automotive Applications Product Specifications

- Heat-shrink tubing mechanical property test

- 1/4 inch

- 220V / 50Hz

- RS232, USB

- Floor Standing

- Digital LCD

- 1200 mm

- Max. 400 mm

- 60-90 Shore A

- 0.5 s

- Customized

- 0-500 N

- Programmable settings, Auto data recording, Overload protection

- Digital, PLC control

- 0.01 N

- 0.5% FS

- 1-5

- 85 kg

- 500 N

- Automotive Wire Harness, Insulation Testing

- 50 mm

- AC 220V 10%

- 50Hz

- Semi-automatic

- 50-500 mm/min

- 0.4~0.8 MPa

- 0 to 500 N

- 20%-90% RH

- 10C~40C

Product Description

Product FeaturesNote1

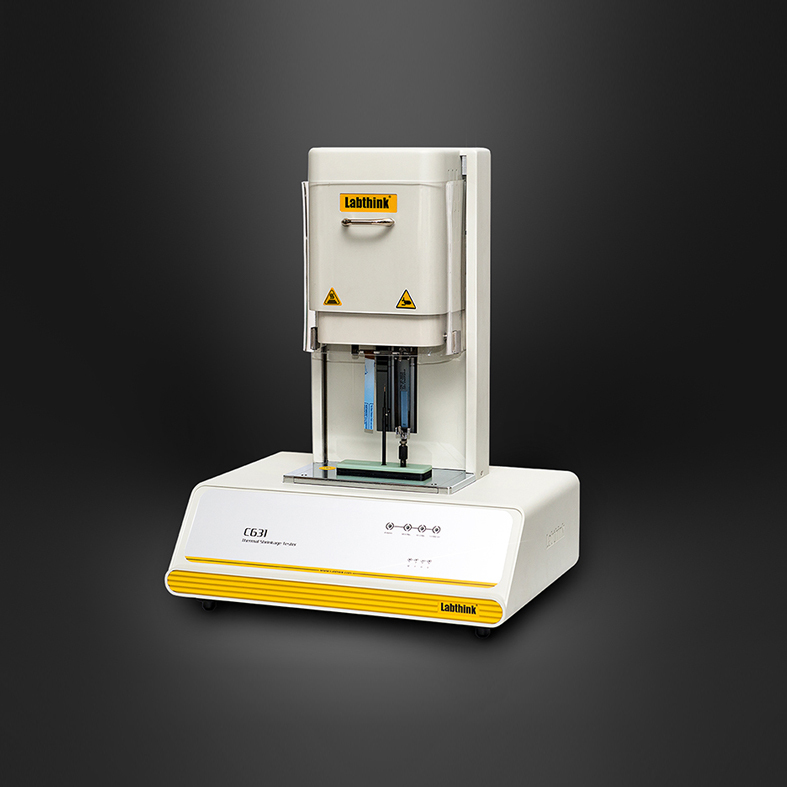

Innovative Laser Measurement Technology providing Higher Precision and Efficiency

- Advanced laser measurement technology, measures thermal shrinkage ratio of film precisely

- High precision load cell supplied by global renowned manufacturer, provides testing accuracy higher than 0.5%FS and better repeatability of test results

- Multiple test ranges can be selected to meet various testing requirements

- Global renowned brand operating control system guarantees the accuracy of displacement and speed

- Three speeds (up to 2 seconds) for loading specimen can be selected

- Shrinking force, contracting force and shrinkage ratio are displayed in real time

Embedded, Secured and Easy-to-use Computer Controlled System

- Integrated design of instrument and software requires no external computer

- Standard monitor, mouse, keyboard and Window operating interface for simplified operation and data display

- Historical data can be reviewed and printed

- USB ports and net ports for external connection and data transmission

- Intelligent reminder for sensor calibration provides safe data processing environment

- Labthinks unique data security design isolates the test data from computer and prevents data loss caused by computer virus

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test Principle

The specimen is placed in the test area for displacement and force measurement, it is then heat to the specified temperature for shrinkage test and cooled down. The system automatically records the shrinking force, temperature and shrinkage ratio in real time and provides analytical results.

Test StandardNote1

GBT34848, ISO-14616-1997, DIN 53369-1976

Applications

| Basic Applications |

|---|

|

|

Technical SpecificationsNote2

| Specification | C631H |

|---|---|

| Load Cell Capacity | 5 N (Standard) 10 N, 30 N (Optional) |

| Force Accuracy | Indicated Value 0.5% (10%-100% of Load Cell Capacity) 0.05%FS (0%-10% of Load Cell Capacity) |

| Force Resolution | 0.001 N |

| Displacement Range | 0.1 95 mm |

| Displacement Accuracy | 0.1 mm |

| Shrinkage Ration Range | 0.1%95% |

| Temperature Range | Room Temperature 210C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Number of Stations | 1 Group (2 pcs) |

| Specimen Size | 110 mm 15 mm (Standard) |

| Instrument Dimension | 480 mm (L) 400 mm (W) 630 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 26 kg |

Configurations

- Standard Configurations

- Instrument, Monitor, Mouse, Keyboard, High-temperature Welding Cloth, T-Plate (10 pcs)

- Optional Parts

- High-temperature Welding Cloth, T-Plate, DataShieldTM Note3

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Advanced Data Handling Capabilities

The tester's dual data storage system-internal memory and external USB support-ensures secure and flexible data management. Detailed test results can be transferred seamlessly to a PC using the included software for thorough analysis and report generation, making compliance documentation and process evaluations straightforward.

Safety and Compliance Assured

Designed to meet industry benchmarks, this equipment adheres to ISO 6722 and UL 224 safety standards. This commitment to compliance ensures that test results are both reliable and recognized within the global automotive sector, granting manufacturers peace of mind regarding regulatory adherence.

Efficient and Versatile Testing Process

With its semi-automatic operation, digital PLC control, manual or automatic sample loading, and programmable features, the tester offers adaptability for different testing requirements. Integrated air cooling maintains optimal temperatures during intensive use, while its powder-coated exterior increases durability for demanding industrial environments.

FAQ's of Testing for Heat-Shrink Tubing for Automotive Applications:

Q: How does the Heat Shrink Tubing Tester store and manage test data?

A: The tester is equipped with internal memory and provides external USB support, allowing users to save, export, and back up test data efficiently. The included PC software further enables comprehensive data analysis and professional report generation.Q: What safety standards does the equipment comply with?

A: This Heat Shrink Tubing Tester meets stringent ISO 6722 and UL 224 standards, ensuring it delivers safe and reliable testing for automotive wire harnesses and insulation applications.Q: When should the tester be calibrated, and what is included for this process?

A: It is recommended to calibrate the tester every 12 months. Calibration blocks are included with the equipment to facilitate precise and reliable calibration procedures.Q: Where is this tester most effectively utilized?

A: This tester is ideally suited for use in automotive manufacturing and testing facilities focused on wire harness and insulation mechanical property evaluation, particularly by manufacturers, suppliers, and exporters in the automotive sector.Q: What is the process for testing heat-shrink tubing using this equipment?

A: Users can load specimens manually or automatically, select programmable test parameters, and initiate testing via digital PLC control. The integrated air cooling system ensures temperature stability throughout the test, and test results are displayed digitally for immediate review.Q: How does the machine benefit automotive applications specifically?

A: By providing accurate mechanical property data for heat-shrink tubing and wire harness insulation, it supports quality assurance, product development, and regulatory compliance in automotive manufacturing, reducing the risk of product failure in the field.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

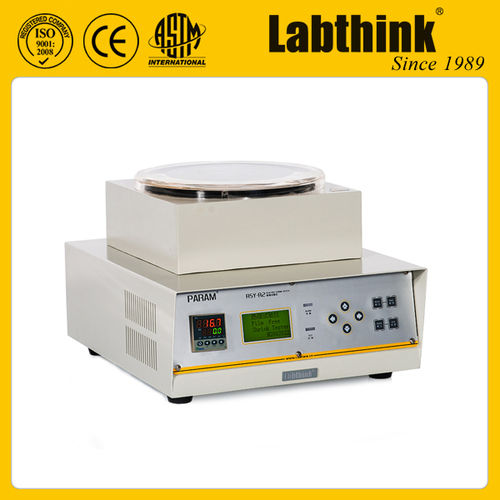

Other Products in 'Thermal Shrinkage Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese