Detection Method Water Vapor Permeability Tester

Product Details:

- Test Range 0.001 ~ 50 g/m224h

- Specimen Size 100 mm Millimeter (mm)

- Gas Pressure 0.12 MPas mpa

- Power Supply 220VAC 50Hz / 120VAC 60Hz

- Temperature 5C ~ 95C Celsius (oC)

- Number of Specimens 1

- Port Size 1/8 inch copper tubing

- Click to View more

Detection Method Water Vapor Permeability Tester Price And Quantity

- 1 Set

- 10000.00 - 130000.00 USD ($)/Set

Detection Method Water Vapor Permeability Tester Product Specifications

- water vapour transmission rate test

- 36 kg Kilograms (kg)

- micro-computer

- 0.001 ~ 50 g/m224h

- 0.12 MPas mpa

- 100 mm Millimeter (mm)

- 0.001 ~ 50 g/m2 24h Cubic Inches (in3)

- 5C ~ 95C Celsius (oC)

- 220VAC 50Hz / 120VAC 60Hz

- 1

- 1/8 inch copper tubing

Detection Method Water Vapor Permeability Tester Trade Information

- 10 Set Per Week

- 7 Days

- Veneer Case

- All India

- ISO 9001, CE

Product Description

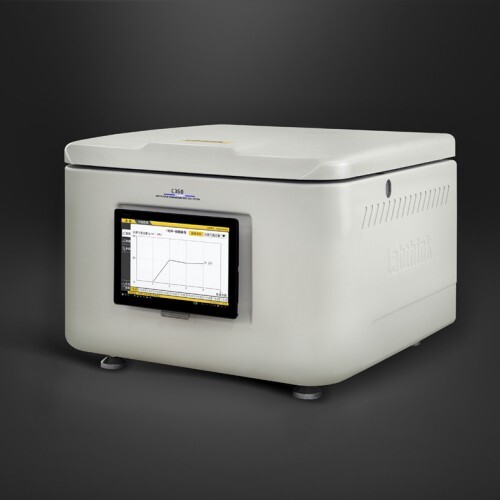

Electrolytic Detection Method Water Vapor Permeability Tester

This apparatus is professionally used for deciding water vapor transmission rate of composite films, plastic films, back-sheets, high barrier materials, sheeting, waterproof materials, aluminum foils, and other things utilized in medical and sanitary industry. By examining the water vapor transmission rate, the practical indexes of materials could be controlled to cater to the necessities for production.

Principle

Below a convinced test temperature, a continuous humidity change is produced amid two sides of the test example. The water vapor infuses via the example into the dry side and at that time is taken to the detector, where relative electric signs will be made. The water vapor transmission degree and other limits can be got by examining and scheming these electrical indications.

Standards

This test instrument imitates to the following values:

- GB/T 21529, ISO 15106-3, YBB 00092003, DIN 53122-2

Basic Applications

Films

-

With plastic films, paper-plastic composite films, plastic composite films, aluminized films, coextruded films, aluminum foil composite films, aluminum foils, and several others

Sheeting

-

Including several sorts of rubber and building materials, engineering plastics, e.g. PVC, PP, and PVDC

Packages

-

Together with plastic, paper, rubber, glass and metal packages, paper-plastic composite, e.g. peanut oil packages, Coke bottles, materials, metal three-piece cans, vacuum bags, plastic packages for soft tubes for toothpaste, cosmetic, yogurt cups and jelly.

Extended Applications

Package Caps

-

Examine seal presentation of dissimilar package caps

Solar Back-Sheets

-

With solar back-sheets

Plastic Pipes

- Counting numerous sorts of pipes, e.g. PPR

- Plastic Packages for Health Care Products and Drugs

- Examine water vapor transmission degree of plastic bottles for health care goods and drug, e.g. infusion bags, eye drop bottles, and health care merchandise packages

Medical items and Related Products

-

Including medical plaster covers, aseptic wound defensive films, face masks and additional materials

Biodegradable Films

-

The oxygen transmission speed is a vital issue that touches biodegradable film features and additional development

LCD Monitor Films

-

With LCD monitor films

Cosmetics

-

Examine water vapor penetrability of cosmetics

Features:

- The tool is regulated by micro-computer with LCD, PVC operating panel and menu interface, that could suitably spread test results, test data, and test curves

- Micro-printer and typical RS232 port for suitable data production and transfer

- Assists LystemTM Lab Data Sharing System for unchanging organization of test consequences and test reports

- Reference film for profligate calibration to confirm precise and worldwide test data

- The system could be protracted for the water vapor transmission degree test of ended package ampules by special customization

- Extensive range and high-precision of involuntary temperature regulator to support mixtures of non-standard test circumstances

Standard Configurations

-

Micro-printer, Mainframe, Continuous Temperature Regulator Device, Exactness Pressure Controller for Nitrogen Cylinder, Desiccant, Porous Ceramic Tray, Vacuum Grease and Round Sample Cutter

Optional Parts

-

Communication Cable and Professional Software

Note

-

The gas supply harbor of the tool is 1/8 inch copper tubing;

- Clienteles will require to make for gas supply, salt reagent and distilled water.

- Specifications

Technical Specifications

Specification

Film Test

Test Range

0001 50 gm224h standard

001 1000 gm224h optional

Number of Specimens

1

Resolution

01ppm

Temperature Range

5C 95C

Temperature Accuracy

01C

Humidity Range

0RH 2RH 985RH 100RH standard is 90RH

Accuracy

1RH

Test Area

3848 cm2

Thickness

1 mm accessories required for thicker specimens

Specimen Size

100 mm

Carrier Gas

99999 High Purity Nitrogen outside of supply scope

Gas Flow

100 mLmin

Gas Supply Pressure

012 MPas

Port Size

18 inch copper tubing

Instrument Dimension

500 mm L x 400 mm W x 360 mm H

Power Supply

AC 220V 50Hz

Net Weight

36 kg

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Water Vapor Transmission Rate Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese