Tape Holding Power Testers

Product Details:

- Resolution 1 min

- Test Range 09999 min (holding time)

- Measuring Range 09999 min

- Mounting Type Bench-top

- Power Supply 220 V AC, 50 Hz

- Display Type Digital timer

- Features Independent timers, anti-vibration base, sample clamping arrangement

- Click to View more

Tape Holding Power Testers Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

Tape Holding Power Testers Product Specifications

- 220 V AC, 50 Hz

- Bench-top

- 09999 min

- 09999 min (holding time)

- Adhesive tape quality control

- 1 min

- 25 mm x 100 mm

- 1040C

- Semi-automatic

- Independent timers, anti-vibration base, sample clamping arrangement

- Digital timer

- Manual release mechanism

- Fixed (gravity based, no variable speed)

- 10100 mm

- Approx. 25 kg

- 50 Hz

- 1 min

- 200 mm

- 350 mm

- 220 V

- 4075% RH

- N/A (No pneumatic ports required)

- Holding Power Tester

- Immediate start/stop upon detachment

- Up to 1 kg per position

- Manual, digital display

- Self-adhesive tape static shear (holding power) test

- 6 positions

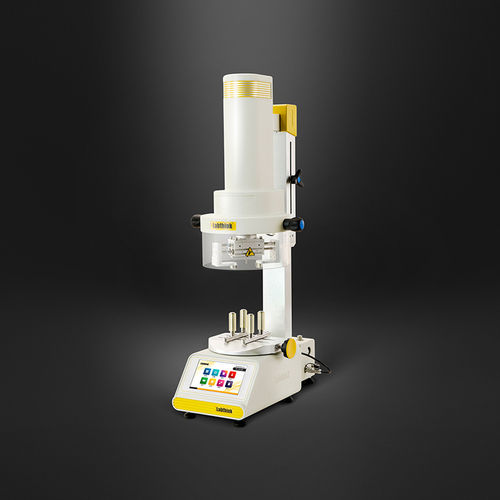

Product Description

Product FeaturesNote1

Multiple Test Mode

- Time method and displacement method

- Standard test plates and weights ensure the accuracy of test data

- Automatic timing, inductance type large area sensor and fast locking functions guarantee the accuracy of test data

- Automatic statistics of maximum value, minimum value, average value and logarithmic reduction value

- Testing environment temperature and humidity curves are displayed and recorded automatically in real time for data comparison under the same conditions

New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, user-friendly interface, remote upgrade and maintenance

- Chinese and English languages can be selected

- Automatic data storage and power failure memory functions to prevent data loss

- Storage up to 1200 test records

- Multi-level user privilege management, log in with password

- Micro-printer and USB data ports for data exporting and data transfer (optional)

Test Principle

The test plate with adhesive specimen is vertically hanged on the stand and its bottom is attached with a standard weight. The lasting adhesive property can be obtained by measuring the displacement of specimen on vertical test plate or the time to failure at such load.

Test StandardNote1

GB/T 4851-2014, ASTM D3654, JIS Z0237

Applications

| Basic Applications |

|---|

|

Technical SpecificationsNote2

| Specifications | CZY-8SA Lasting Adhesive Tester |

|---|---|

| Standard Roller | 2000 g 50 g |

| Weight | 1000 g 5g (with hook) |

| Test Plate A | 125 mm (L) 50 mm (W) 1.3 mm (D) |

| Timing Range | 0 9999 hrs 59 min 59 sec |

| Number of Stations | 8 |

| Instrument Dimension | 900mm(L)315mm(W)544mm(H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 25 kg |

Configurations

- Standard Configurations

- Instrument, Test Plate A (Vertical), Weight (1000g), Triangle Hook, Standard Roller

- Optional Parts

- Test Plate B (Horizontal), Weight (4500g), NIST SRM1810A Fiber Plate, Micro Printer

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Robust Construction and Corrosion Resistance

Engineered from mild steel and finished with a durable, corrosion-resistant powder coating, the tester is built to withstand rigorous usage in laboratories and production facilities alike. Its anti-vibration base ensures stability and measurement integrity, while the bench-top design facilitates easy installation and operation.

Accurate and User-friendly Timing

The integrated microprocessor-based digital timer provides precise measurement of holding power with a resolution of 1 minute and 1 minute accuracy. Each of the six specimen positions has an independent timer, enabling simultaneous but independent testing with immediate response upon tape detachment.

Compliant and Versatile Testing

Compliant with industry-leading standards (ASTM D3654, PSTC-7), this holding power tester is suitable for a range of self-adhesive tape quality assessments. It accommodates tape widths from 10-100 mm, supports up to 1 kg per sample, and operates reliably within 10-40C temperature and 40-75% humidity ranges.

FAQ's of Tape Holding Power Testers:

Q: How does the tape holding power tester measure holding power?

A: The tester measures the holding power of adhesive tapes by suspending a weight from the tape, which is affixed to a fixed vertical panel. A microprocessor-based digital timer starts immediately upon sample loading and stops as soon as the tape detaches, recording the exact holding duration.Q: What is the process for preparing and testing specimens on this equipment?

A: Prepare tape samples measuring 25 mm x 100 mm, attach them to the test panel, and hang the specified weight (up to 1 kg per position). Once set, manually release the samples using the provided release mechanism. The timer for each position will automatically begin, registering the holding time until adhesive failure.Q: What standards does the equipment comply with for testing?

A: This tape holding power tester complies with ASTM D3654 and PSTC-7 standards, ensuring reliable and industry-accepted evaluation methods for static shear testing of self-adhesive tapes.Q: When and where can this tester be used effectively?

A: Ideal for laboratories and industrial quality control departments, the tester functions optimally in environments with 40-75% relative humidity and temperatures ranging from 10-40C. Its bench-top design allows for convenient placement in workspace settings.Q: What is included in the package content of the tape holding power tester?

A: The package contains the main tester unit, hanging weights for applying test loads, and a user manual to guide setup and operation processes.Q: What are the advantages of using independent digital timers for each specimen?

A: Independent timers enable simultaneous testing of multiple samples (up to six), ensuring each test position is recorded accurately and without cross-interference. This feature increases testing throughput and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese