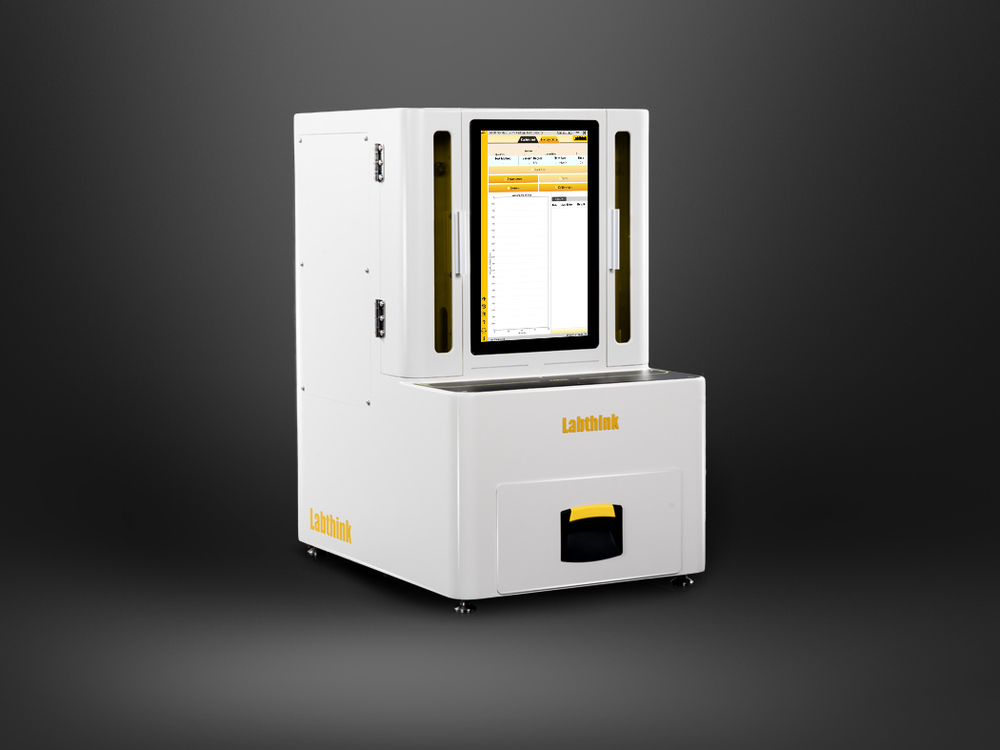

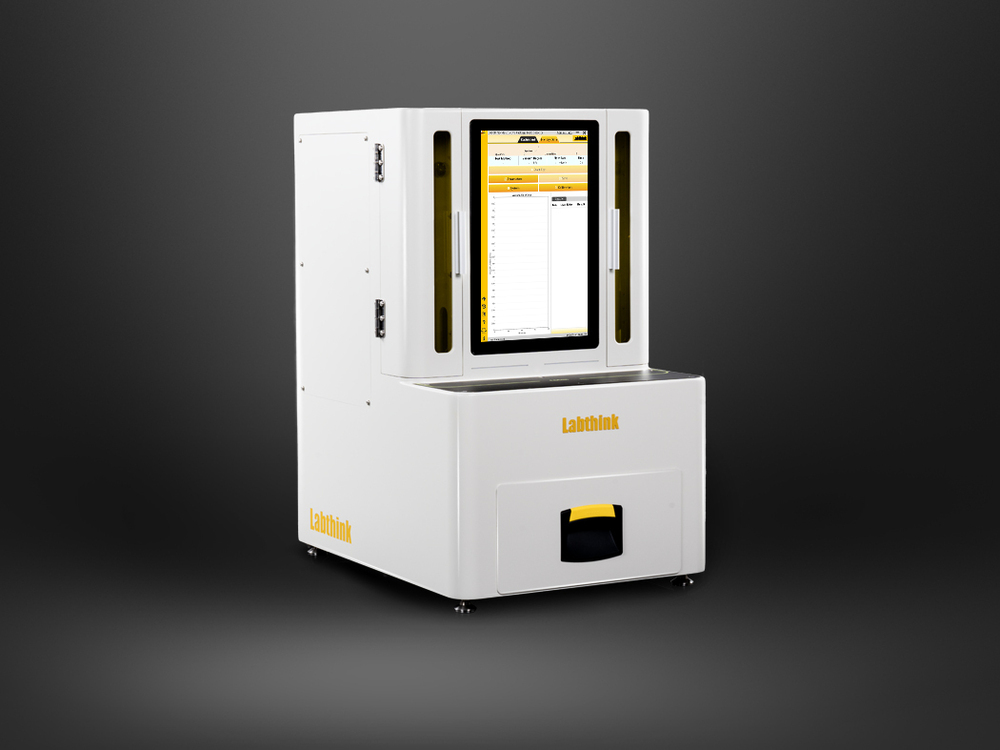

Leakage Detection Equipment

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Humidity 35-85% RH

- Automation Grade Automatic

- Mounting Type Table Top

- Number of Specimens 1

- Port Size 6 mm

- Response Time 1 s

- Display Type LCD Display

- Click to View more

X

Leakage Detection Equipment Price And Quantity

- 2000.00 - 20000.00 USD ($)/Set

- 1 Set

Leakage Detection Equipment Product Specifications

- Industrial Leakage Detection

- 45 kg

- 1-5 L/min

- 15-45C

- 0.5% FS

- Leakage Testing for Sealed Containers

- Leakage Detection Equipment

- 220V AC

- 50 Hz

- AC 220V, 50Hz

- 0-600 mm

- Digital/RS232

- 280 mm

- 0.01 mm

- LCD Display

- 0-600 mm

- 80-500 mm/min

- 0-700 mm

- 400 mm

- 60 mm x 280 mm

- Microprocessor Control

- 0.4-0.7 MPa

- Automatic Test, Alarm System, High Sensitivity

- 35-85% RH

- 1

- Automatic

- Table Top

- 6 mm

- 1 s

Leakage Detection Equipment Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Technical Specifications- Test Range 0~600 KPa; 0~87.0 psi (standard) 0~1.6 MPa; 0~232.1 psi (optional)

- Gas Injection Head 10 mm (standard)4 mm, 1.6 mm (optional)

- Gas Supply Pressure 0.4 MPa~0.9 MPa (outside of supply scope)

- Port Size 8 mm PU Tubing

- Instrument Dimension 300 mm (L) x 310 mm (W) x 180 mm (H)

- Pedestal Size 305 mm(L) x 356 mm(W) x 325 mm(H)

- Power Supply AC 220V 50Hz

- Net Weight 23 kg

Advanced Sensor Technology

Equipped with high-sensitivity pressure sensors, this leakage detection equipment provides accurate and reliable measurement up to 0.5% FS with a resolution of 0.01 mm. The automated process minimizes error, offering fast response times (1 s). Audible and visual alarms ensure immediate notification upon detection of leaks, improving safety and operational efficiency in industrial environments.

Robust Design and Flexible Operation

Built with powder-coated steel and IP54 rated for dust and splash protection, this equipment is designed for longevity and challenging factory conditions. The system features microprocessor control and adjustable test parameters, handling specimen sizes up to 60 x 280 mm and capacities of 1-5 L/min. Its versatile mounting and automated functions make it ideal for manufacturers, exporters, and suppliers.

Comprehensive Data Management and Software

Featuring USB and RS232 digital interfaces, the system allows seamless data transfer to PCs for thorough analysis. Included PC-based software supports calibration, monitoring, and reporting functions, facilitating consistent record-keeping and quality control. Its LCD display provides clear test readings, supporting efficient workflow for users.

FAQs of Leakage Detection Equipment:

Q: How does the leakage detection equipment operate using compressed air?

A: The equipment introduces compressed air into the sealed container and utilizes a pressure sensor to monitor for drops in pressure, indicating potential leaks. The automatic test sequence is handled by the microprocessor, ensuring consistent and repeatable results.Q: What types of alarm functions are included in this detection equipment?

A: It is equipped with both audible and visual alarm systems that quickly alert operators if leakage is detected during testing, safeguarding quality and enabling prompt corrective action.Q: When should calibration be adjusted for this equipment?

A: The system comes factory calibrated but allows for user adjustment when changing specimen types or test mediums. Regular calibration ensures accuracy within the 0.5% FS specification and should be performed following any relocation or maintenance.Q: Where is this leakage detection equipment suitable for installation?

A: Designed for industrial environments, it is ideal for table-top mounting in production facilities, quality control labs, and inspection stations. Its durable, powder-coated steel housing and IP54 protection make it well-suited for areas where dust and splashing can occur.Q: What is the process for conducting a leakage test with this system?

A: Place the specimen within the test chamber, set test parameters on the microprocessor, and initiate the automated sequence. The pressure sensor monitors the specimen in real-time, and results are displayed on an LCD screen, with alarms activated if a leak is found.Q: How can users benefit from the included PC-based software?

A: The software enables detailed analysis, report generation, and remote control of tests. It simplifies data management and enhances tracking of testing histories, helping producers and quality control personnel comply with rigorous industrial standards.Q: What are the main advantages of using this equipment for industrial leakage detection?

A: Its automatic operation, high sensitivity, robust construction, and consistent accuracy streamline leakage testing, saving time and reducing error. The combination of digital interfaces and software support improves efficiency for dealers, exporters, fabricators, and manufacturers in China and beyond.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese