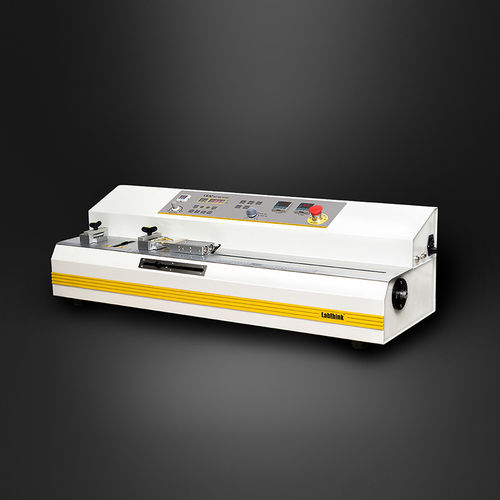

Flex Durability Tester for Simulating Real-World Stresses

50000 USD ($)/Set

Product Details:

- Gas Pressure 0.4-0.7 MPa

- Resolution 1 cycle

- Mounting Type Bench-top

- Display Type Digital LCD

- Features Auto-stop, test count preset, over-current protection

- Equipment Type Flex Durability Tester

- Accuracy 1 cycle

- Click to View more

X

Flex Durability Tester for Simulating Real-World Stresses Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Flex Durability Tester for Simulating Real-World Stresses Product Specifications

- AC 220V, 50Hz

- 50/60 Hz

- Semi-automatic

- 220V AC

- 10%85% RH

- Instant

- 6 mm (air inlet)

- 0-999,999 cycles

- Standard: 70 x 45 mm; custom optional

- N/A (not applicable)

- 400 mm

- 10C40C

- 100-300 cycles/min adjustable

- Up to 6 simultaneously

- 52 kg

- Up to 80 mm

- Lab/industrial sample flex testing

- Min: 100 cycles; Max: 999,999 cycles

- Standard, up to 6 test arms

- Simulating real-world mechanical flexing of materials such as leather, fabrics, plastics, rubber, coated materials

- Push button/Rotary dial

- Digital control panel

- 20-120 mm adjustable

- 0.4-0.7 MPa

- Auto-stop, test count preset, over-current protection

- Bench-top

- Digital LCD

- 1 cycle

- Flex Durability Tester

- 1 cycle

Product Description

Product FeaturesNote1

Multiple Test Modes & High Testing Efficiency

- Five standard test modes including condition A, B, C, D, E and one customized mode F, in which the user can set test cycles freely

- Four stations improve the testing efficiency

- Fast switch between long and short stroke

- Testing environment temperature and humidity are displayed in real time and automatically recorded for data comparison

Renowned Brand Servo Control System with Ultra-long Service Life and Ultra-low Failure Rate

- The instrument is controlled by servo motor, which provides more accurate displacement

- Dual protection for hardware and software as well as auto reset provides a safe operating environment for customers

New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, user-friendly interface, remote upgrade and maintenance

- Chinese and English languages can be selected

- Automatic data storage and power failure memory functions

- Historical data can be reviewed and printed easily

- Storage up to 1200 test records

- Multi-level user privilege management, log in with password

- Micro-printer for data exporting and data transfer (optional)

Test StandardNote1

ASTM F392

Applications

| Basic Applications |

|---|

|

|

Technical SpecificationsNote2

| Specification | C681M Flex Durability Tester |

|---|---|

| Flex Frequency | 45 cpm |

| Test Mode | Condition A (2700 cycles), Condition B (900 cycles), Condition C (270 cycles), Condition D (20 cycles), Condition E (20 cycles partial flex), Condition F (020000 cycles) |

| Tensile & Pressing Force | 300 N |

| Torque | 2 Nm |

| Specimen Thickness | 2.5mm (Sample clamps are needed for other thickness specimen) |

| Flex Angle | 440 / 400 |

| Horizontal Stroke | 155 mm / 80 mm |

| Number of Stations | 4 |

| Number of Specimens | 1 4Note3 |

| Specimen Size | 280 mm x 200 mm |

| Instrument Dimension | 760 mm (L) 410mm (W) 650mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 85 kg |

Configurations

- Standard Configurations

- Instrument, Adjustable Positioning Ring

- Optional Parts

- Micro-printer, Sample Cutter and Hose Clamp 64(91mm 114mm)

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: Multiple specimens share the tensile & pressing force and the torque.

Advanced Clamping and Control for Flexible Testing

With quick-release clamps and a user-friendly digital control panel, the Flex Durability Tester streamlines the sample preparation process. Adjustable parameters such as test speed and stroke provide flexibility for a range of test scenarios and material types, ensuring accurate and repeatable results in every cycle.

Reliability, Safety, and Compliance Built In

Safety is prioritized through features like over-travel prevention, emergency stop functions, and over-current protection. Its precision brushless DC motor, digital cycle counter, and robust construction meet international flex testing standards (ISO, ASTM, DIN), making it an industry benchmark for repeatable reliability.

Versatile Applications Across Material Types

Engineered for diverse applications, the tester evaluates the flex durability of leather, fabrics, rubber, plastics, and more. With capabilities for up to 6 specimens and support for custom sizes, it offers tailored testing solutions suitable for manufacturers, exporters, and research labs.

FAQ's of Flex Durability Tester for Simulating Real-World Stresses:

Q: How does the Flex Durability Tester simulate real-world mechanical stresses?

A: The tester reproduces repeated flexing motions with adjustable speed (100-300 cycles/min) and stroke (20-120 mm), subjecting specimens to conditions that closely mimic actual use. This process reveals how materials behave and wear under continual movement, aiding in product development and quality assurance.Q: What types of materials can be tested with this equipment?

A: You can use the Flex Durability Tester to evaluate leather, textile fabrics, rubber, plastics, and coated materials. Its versatile clamping system supports standard (70 x 45 mm) and optional custom specimen sizes, accommodating a wide range of industrial and laboratory samples.Q: When is it appropriate to use the auto-stop and cycle preset features?

A: Auto-stop is used to halt the test automatically once a pre-set number of cycles or a test objective is reached, preventing over-testing or specimen damage. This is especially useful when adhering to specific testing protocols or industry standards that define test lengths.Q: Where can the Flex Durability Tester be installed and operated safely?

A: This bench-top machine is designed for laboratories and industrial settings free from corrosive gases, strong vibrations, and electromagnetic interference. Ensure operating conditions are within 10-40C and 10%-85% RH humidity, with a stable AC 220V, 50Hz power supply.Q: What steps are involved in setting up and running a flex test?

A: First, prepare and mount up to six specimens using the quick-release clamps. Select the desired test parameters via the digital control panel-speed, stroke, and cycle count. Initiate testing and monitor progress on the LCD display, utilizing features like emergency stop and digital cycle counter for safety and precision.Q: How does onsite or remote technical support benefit users?

A: Professional technical support ensures users can quickly resolve operational questions or troubleshoot issues, minimizing downtime. Whether remotely or onsite, this service aids with calibration, maintenance, software updates, and training, maximizing the machine's performance and lifespan.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese