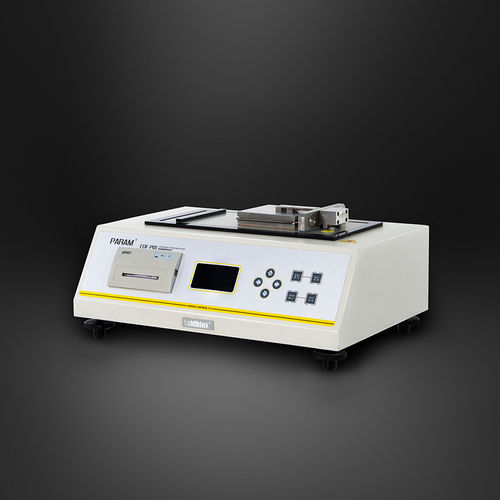

Papers and Films Coefficient Of Friction (Cof) Tester

50000 USD ($)/Set

Product Details:

- Measuring Range 0-1.00 CoF

- Port Size Standard 6 mm air port

- Gas Pressure 0.5 MPa (if applicable for air type specimens)

- Accuracy 1% of reading

- Temperature 15C - 35C

- Interface Type USB/RS232 data output

- Equipment Type Coefficient of Friction (COF) Tester

- Click to View more

X

Papers and Films Coefficient Of Friction (Cof) Tester Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Papers and Films Coefficient Of Friction (Cof) Tester Product Specifications

- 0.001 CoF

- 40% - 85% RH

- NA for tester

- 150 mm

- 50/60 Hz

- 100 mm/min (adjustable)

- 180 mm

- 220V AC 10%, 50/60Hz

- <2 seconds

- 1 (single-run test possible)

- 0.01 - 1.00 CoF

- 220V AC, 50 Hz

- Semi-automatic

- Coefficient of Friction (COF) Tester

- Laboratory testing of slip and friction for flexible packaging

- Real-time graph plotting, Auto-calibration, Data storage

- Bench-top

- Digital LCD display

- Microprocessor based digital control

- Testing static and kinetic coefficient of friction of papers, films and flexible packaging materials

- 80 mm x 200 mm

- 32 kg

- Standard 6 mm air port

- 0-1.00 CoF

- 1% of reading

- 0.5 MPa (if applicable for air type specimens)

- 15C - 35C

- 3 N / 5 N / 10 N load cell options

- 80 mm

- USB/RS232 data output

Product Description

Features

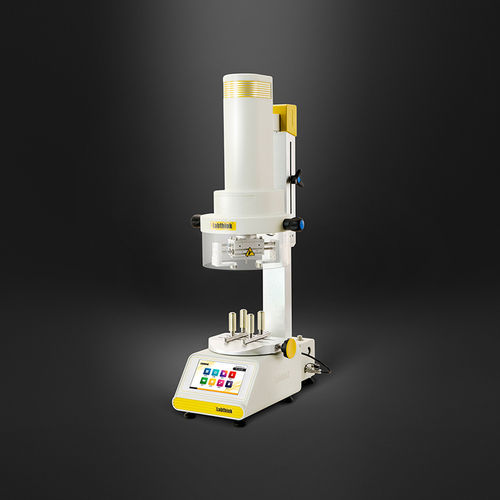

- The instrument is professionally applicable to the determination of static coefficients of friction of specimens on the inclined surface

- The functions of freely changeable angular velocity and automatic plane reset support combinations of non-standard test conditions

- The sliding plane and the sled are treated by degaussing and remanence detection which effectively reduce the system errors

- The instrument is controlled by micro-computer with LCD, PVC operation panel and menu interface, which is convenient for customers to test or view the test data

- Equipped with micro-printer and RS232 port for convenient PC connection and data transfer

- Supports LystemTM Lab Data Sharing System for uniform and systematic data management

Standards

This instrument conforms to the following standards:

ASTM D202, ASTM D4918, TAPPI T815

Applications

The instrument is applicable to the determination of static coefficients of friction of:

| Basic Applications |

|---|

|

|

| Extended Applications |

|

|

Technical Specifications

| Specifications | COF-P01 |

|---|---|

| Angle Range | 0 85 |

| Accuracy | 0.01 |

| Angular Velocity | 0.1/s 10.0/s |

| Specifications of Sled | 1300 g (standard) |

| 235 g (optional) | |

| 200 g (optional) | |

| Customization is available for other masses | |

| Ambient Conditions | Temperature: 232C |

| Humidity: 20%RH 70%RH | |

| Instrument Dimension | 440 mm (L) x 305 mm (W) x 200 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 20 kg |

Configurations

- Standard Configurations

- Instrument, Micro Printer and Sled of 1300g

- Optional Parts

- Professional Software, Communication Cable, Sled of 235g, Sled of 200g and Customized Sled

Advanced Testing Capabilities for Paper and Film

This COF tester offers both static and kinetic coefficient evaluation, supported by high-precision load cells (3N, 5N, 10N) and real-time digital feedback. Test speed, width, and stroke are adjustable, enabling reliable slip and friction analysis across diverse flexible packaging substrates.

User-Friendly Digital Interface and Connectivity

A clear LCD display, microprocessor-based controls, and PC software integration streamline data collection and reporting. Results are easily stored and exported via USB or RS232 ports for comprehensive analysis, providing a seamless laboratory experience.

Comprehensive Safety and Calibration Features

Equipped with overload protection, emergency stop, and both automatic and manual calibration, the tester ensures accuracy and operator safety. The included sliding sled, calibration weights, and detailed user manual support efficient set-up and reliable routine testing.

FAQ's of Papers and Films Coefficient Of Friction (Cof) Tester:

Q: How does the COF tester measure the coefficient of friction for various materials?

A: The tester measures both static and kinetic coefficients of friction by sliding a weighted sled (200g) across the specimen material (paper, film, laminate) at controlled speeds. The force required is detected by the load cell and digitally displayed, with results compliant to ASTM D1894, ISO 8295, and TAPPI T816 standards.Q: What types of materials and specimen sizes are compatible with this tester?

A: This instrument is compatible with paper, plastic films, laminates, and flexible packaging sheets. It is designed for specimen sizes of 80 mm x 200 mm, supporting single-run tests to accommodate various laboratory quality control requirements.Q: When should calibration be performed on the device, and what options are available?

A: Calibration should be conducted during initial setup, after maintenance, or if accuracy is in doubt. The device provides both automatic and manual calibration functions, ensuring reliable results aligned with international standards.Q: Where is the optimal environment for operating this COF tester?

A: Operation is recommended in a dust-free laboratory, within temperature and humidity ranges of 15C to 35C, and 40%-85% relative humidity, to maintain precision and instrument longevity.Q: What is the process for retrieving and analyzing test data?

A: Test results are displayed instantly on the digital LCD and can be saved in the onboard memory (up to 1000 results). For advanced analysis, data can be exported to a PC using supported software via USB or RS232, allowing detailed reporting and real-time graph plotting for further evaluation.Q: How does using this COF tester benefit laboratory testing?

A: Using this device provides fast, accurate, and repeatable friction results essential for quality assurance in flexible packaging. The automated data handling and real-time graphing features streamline workflows and uphold quality compliance, supporting faster decision making in R&D and production settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese