Shrinkage Testing of Heat-Shrink Tamper-Evident Seals for Pharmaceutical Products

Product Details:

- Features Digital controls, overheat protection, auto calibration

- Gas Pressure 0.20.6 MPa

- Power Supply 230 V AC, 50 Hz

- Frequency 50 Hz

- Test Range Up to 250C shrinkage

- Port Size 1/4 inch NPT

- Accuracy 0.5 mm

- Click to View more

Shrinkage Testing of Heat-Shrink Tamper-Evident Seals for Pharmaceutical Products Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Shrinkage Testing of Heat-Shrink Tamper-Evident Seals for Pharmaceutical Products Product Specifications

- 0-100 mm

- 3585% RH

- Large digital LCD display

- 0100 mm shrinkage measurement

- Semi-automatic

- Digital Shrinkage Tester

- <2 sec

- Room temperature, 1535C

- 230 V, 50 Hz

- RS232 serial interface

- 0.5 mm

- Up to 250C shrinkage

- 1/4 inch NPT

- Approx. 18 kg

- 50 Hz

- Digital controls, overheat protection, auto calibration

- 230 V AC, 50 Hz

- 0.20.6 MPa

- Heat-shrink tamper-evident seal shrinkage testing for pharmaceutical products

- 150 mm

- 0.01 mm

- Microprocessor based digital control

- Standard: 500N

- Diameter: 1050 mm; Length: 20120 mm

- 50 mm/min (standard); adjustable 10200 mm/min

- Pharmaceutical packaging QC

- Up to 3 per test cycle

- Bench top

- Up to 100 mm

Product Description

Product FeaturesNote1

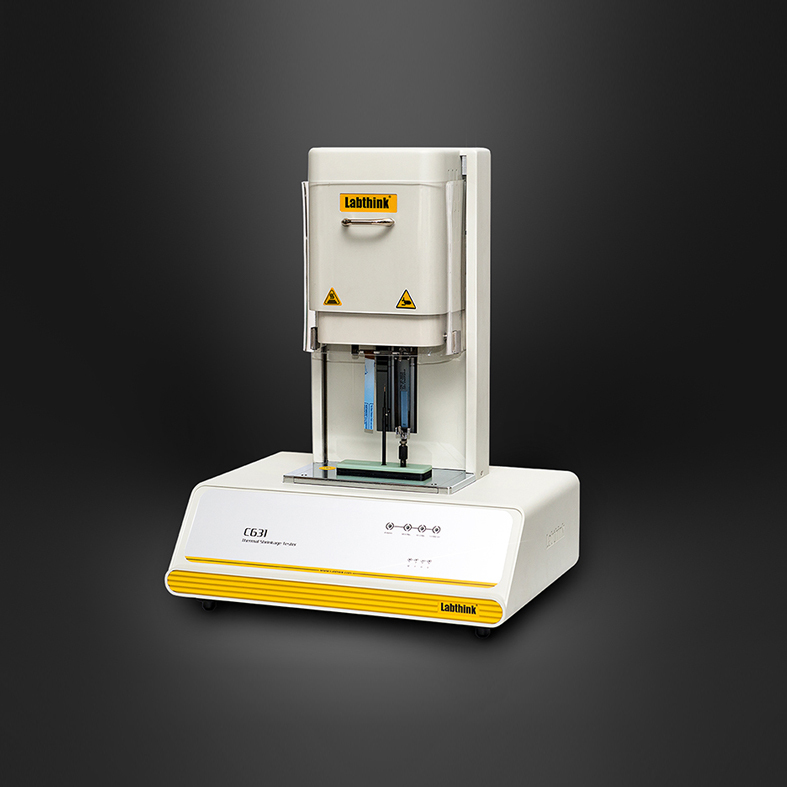

Innovative Laser Measurement Technology providing Higher Precision and Efficiency

- Advanced laser measurement technology, measures thermal shrinkage ratio of film precisely

- High precision load cell supplied by global renowned manufacturer, provides testing accuracy higher than 0.5%FS and better repeatability of test results

- Multiple test ranges can be selected to meet various testing requirements

- Global renowned brand operating control system guarantees the accuracy of displacement and speed

- Three speeds (up to 2 seconds) for loading specimen can be selected

- Shrinking force, contracting force and shrinkage ratio are displayed in real time

Embedded, Secured and Easy-to-use Computer Controlled System

- Integrated design of instrument and software requires no external computer

- Standard monitor, mouse, keyboard and Window operating interface for simplified operation and data display

- Historical data can be reviewed and printed

- USB ports and net ports for external connection and data transmission

- Intelligent reminder for sensor calibration provides safe data processing environment

- Labthinks unique data security design isolates the test data from computer and prevents data loss caused by computer virus

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test Principle

The specimen is placed in the test area for displacement and force measurement, it is then heat to the specified temperature for shrinkage test and cooled down. The system automatically records the shrinking force, temperature and shrinkage ratio in real time and provides analytical results.

Test StandardNote1

GBT34848, ISO-14616-1997, DIN 53369-1976

Applications

| Basic Applications |

|---|

|

|

Technical SpecificationsNote2

| Specification | C631H |

|---|---|

| Load Cell Capacity | 5 N (Standard) 10 N, 30 N (Optional) |

| Force Accuracy | Indicated Value 0.5% (10%-100% of Load Cell Capacity) 0.05%FS (0%-10% of Load Cell Capacity) |

| Force Resolution | 0.001 N |

| Displacement Range | 0.1 95 mm |

| Displacement Accuracy | 0.1 mm |

| Shrinkage Ration Range | 0.1%95% |

| Temperature Range | Room Temperature 210C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Number of Stations | 1 Group (2 pcs) |

| Specimen Size | 110 mm 15 mm (Standard) |

| Instrument Dimension | 480 mm (L) 400 mm (W) 630 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 26 kg |

Configurations

- Standard Configurations

- Instrument, Monitor, Mouse, Keyboard, High-temperature Welding Cloth, T-Plate (10 pcs)

- Optional Parts

- High-temperature Welding Cloth, T-Plate, DataShieldTM Note3

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Precision Shrinkage Testing for Pharmaceutical Seals

Designed to meet demanding QC requirements, this Digital Shrinkage Tester evaluates the shrinkage properties of heat-shrink tamper-evident seals for pharmaceuticals. Controlled heating, high-accuracy measurement, and adjustable test parameters ensure consistent, reliable results-helping manufacturers maintain compliance and package integrity.

Safety and Compliance for Peace of Mind

Built-in safety features like a thermal cut-off switch and automatic shutoff at excess temperatures protect both operator and product. Adhering to ASTM and ISO standards, the tester is a trusted tool for pharmaceutical quality assurance. Factory calibration and easy in-field recalibration support continued accuracy.

User-Friendly Operation and Flexible Reporting

The digital interface simplifies setup and monitoring. Test progress is displayed on a large LCD, and test reports can be printed directly via the RS232 port. The adjustable holder supports various seal sizes, and up to three specimens can be analyzed per cycle for efficient workflow.

FAQ's of Shrinkage Testing of Heat-Shrink Tamper-Evident Seals for Pharmaceutical Products:

Q: How does the Digital Shrinkage Tester ensure accurate measurement of seal shrinkage?

A: The tester uses a microprocessor-based digital control system and a PID managed heating element to maintain precise temperature stability. Measurement accuracy is ensured with a 0.5 mm tolerance and resolution down to 0.01 mm, allowing for reliable and reproducible results.Q: What types of tamper-evident seals can be tested with this equipment?

A: This instrument accommodates heat-shrink tamper-evident seals used in pharmaceutical packaging. The adjustable stainless steel fixture allows for specimen diameters from 10 to 50 mm and lengths from 20 to 120 mm, covering common pharmaceutical seal sizes.Q: When should I calibrate the Digital Shrinkage Tester?

A: The tester comes factory calibrated for immediate use. For ongoing accuracy, in-field recalibration is recommended periodically based on your internal QC policy or whenever accuracy verification indicates a deviation.Q: Where is the Digital Shrinkage Tester best placed for operation?

A: It is designed for benchtop mounting in environments free from corrosive gases and strong vibrations. An ambient temperature range of 15-35C with 35-85% relative humidity supports optimal operation.Q: What is the testing process for seal shrinkage?

A: Place up to three seal specimens in the adjustable stainless steel fixture. Set test parameters, including temperature (up to 250C) and speed (10-200 mm/min). The tester measures shrinkage along a 0-100 mm stroke, and data is displayed and can be printed via the RS232 port.Q: How can I benefit from using this shrinkage tester in pharmaceutical QC?

A: By ensuring seals shrink and perform as intended, this device helps maintain packaging integrity and product safety. Digital automation, high reliability, and compliance with ASTM/ISO standards streamline testing processes and regulatory adherence.Q: Is data output and reporting supported on this device?

A: Yes, the Digital Shrinkage Tester includes an RS232 serial interface, allowing printable reports and easy data transfer for documentation and analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Thermal Shrinkage Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese