Printing Quality Ink Abrasion Resistance Test to Guarantee High-Quality Cosmetic Packaging

50000 USD ($)/Set

Product Details:

- Temperature 10C 40C

- Operating Voltage 220V AC

- Humidity 20% 80% RH

- Max Height 180 mm

- Resolution 1 cycle

- Specimen Size 60 mm x 100 mm

- Mounting Type Benchtop

- Click to View more

X

Printing Quality Ink Abrasion Resistance Test to Guarantee High-Quality Cosmetic Packaging Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Printing Quality Ink Abrasion Resistance Test to Guarantee High-Quality Cosmetic Packaging Product Specifications

- Up to 3

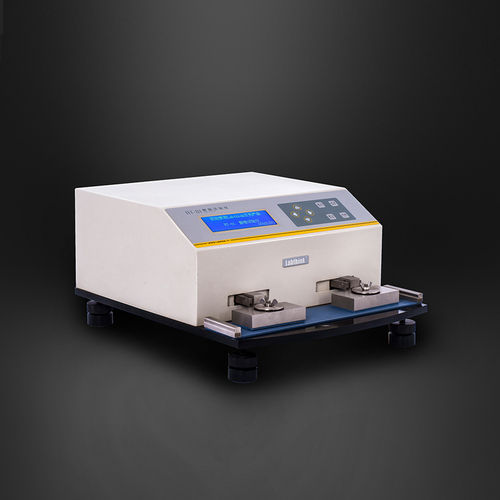

- Abrasion Resistance Tester

- 0 9999 cycles

- 0 9999 abrasion cycles

- 21, 42, 85 cpm (cycles/min)

- Standard 8 mm

- AC 220V, 50Hz

- Approx. 32 kg

- 50/60 Hz

- RS232 / USB

- Semi-automatic

- 20% 80% RH

- 180 mm

- 1 cycle

- Digital Touch Screen

- 10C 40C

- 220V AC

- Benchtop

- 60 mm x 100 mm

- Cosmetic packaging material ink abrasion resistance test

- 0.6 MPa

- Maximum 60 mm

- Programmable cycles, automatic stop, multi-station test, user-friendly interface

- 1 cycle

- 60 mm 1 mm

- Touch Screen LCD

- Laboratory/Industrial

- 1 second

- 3 stations

- Standardized abrasion head

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Advanced Abrasion Testing Technology

Employing a standardized high-carbon steel abrasion head and robust construction, this tester delivers consistent and accurate measurements of ink abrasion on cosmetic packaging. The digital touch screen enables precise control of test parameters, and programmable cycles allow for tailored resistance assessments across a test width of up to 60 mm and strokes of 60 mm 1 mm.

Intuitive Operation and Rapid Data Access

The tester features a user-friendly manual quick lock clamping system, multi-station capability, and digital data display. Data can be exported swiftly using USB or RS232, ensuring test documentation is both secure and accessible. Automated test stops enhance efficiency, while the compact benchtop design suits most laboratory setups.

Optimized for Reliability and Versatility

Operating within a temperature range of 10C to 40C and 20% - 80% relative humidity, this instrument supports various usage environments. It excels in high-throughput settings, supporting up to three specimens simultaneously and processing tests at speeds up to 85 cycles per minute, rendering it ideal for both manufacturer and supplier quality assurance protocols.

FAQ's of Printing Quality Ink Abrasion Resistance Test to Guarantee High-Quality Cosmetic Packaging:

Q: How is the abrasion resistance test performed using this equipment?

A: The test begins by manually clamping up to three specimens (60 mm x 100 mm) into place using the quick lock system. The tester, controlled via a digital touch screen, applies repetitive abrasion cycles with a high-carbon steel head. Programmable cycles allow for specific test ranges, and results are recorded digitally for precise evaluation.Q: What benefits does this abrasion resistance tester provide for cosmetic packaging manufacturers?

A: This tester ensures packaging remains visually appealing and durable, even after extended handling and transportation. Accurate results help manufacturers maintain quality control, meet industry standards, and reduce the risk of product returns due to print degradation.Q: When should an ink abrasion resistance test be conducted?

A: Tests are recommended during both the development and production phases of cosmetic packaging to verify ink adhesion quality and durability. Regular verification ensures high standards prior to shipment and helps rapidly identify process or material issues.Q: Where can this abrasion resistance tester be used?

A: Designed for bench-top use, the machine is ideal for laboratory and industrial quality control settings, including manufacturing lines and material testing labs in the cosmetic packaging industry.Q: What is the process for exporting test data from the instrument?

A: Test results can be retrieved via digital printout, USB export, or RS232 interface. The touch screen LCD facilitates direct operation, while USB and RS232 options allow quick transfer to external data systems for record-keeping or further analysis.Q: How does the equipment ensure user safety and minimal disruption?

A: The abrasion resistance tester operates below 60 dB(A), ensuring a quiet workspace. Its robust construction and user-friendly interface reduce handling risk, while automated test stop features enhance operational safety and consistency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese