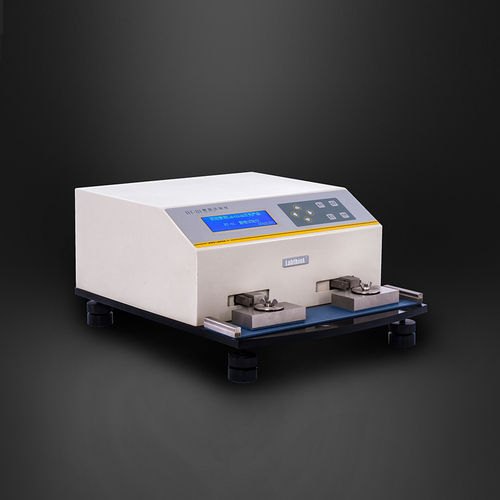

Air Permeability Tester to test textile materials according to ISO 9237

Product Details:

- Operating Voltage AC 220V 10%, 50Hz

- Number of Specimens 1 at a time

- Humidity Relative Humidity 35-80% RH (operating range)

- Equipment Type Laboratory air permeability tester

- Max Height Approx. 45 cm

- Interface Type RS232/USB (for data export)

- Hardness Test Chamber: 55-60 HRC

- Click to View more

Air Permeability Tester to test textile materials according to ISO 9237 Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

- 1 Set

Air Permeability Tester to test textile materials according to ISO 9237 Product Specifications

- Tabletop

- 2 seconds

- Digital display (LCD/LED)

- AC 220V, 50/60 Hz

- 50/60 Hz

- 10C - 40C (operating range)

- 0.1 mm/s

- Textiles, nonwovens, technical fabrics, paper, and similar materials

- Digital reading, multi-nozzle selection, auto-calibration, safe cover, silent operation

- Semi-automatic

- 100 mm

- 0.1 to 12000 mm/s (typically 10 to 10,000 mm/s)

- Standard 100 cm nozzle (customizable: 5, 10, 20, 50, 100 cm)

- 2% of reading

- Test Chamber: 55-60 HRC

- 20 x 20 cm

- 0~3000 Pa (adjustable)

- 0.1 to 12000 mm/s (air permeability)

- Standard 20 cm (Can be customized)

- Digital display & button control

- Approx. 45 cm

- Adjustable, typically 20-200 mm/min

- RS232/USB (for data export)

- 1 at a time

- AC 220V 10%, 50Hz

- Relative Humidity 35-80% RH (operating range)

- Laboratory air permeability tester

- Lab Testing Instrument

- Standard and high-capacity models available

- About 48 kg

Product Description

Product FeaturesNote1

- Two measurement methods of constant pressure difference and constant flow can be freely selected.

- High precision electronic air flow and air pressure sensors ensure the accuracy of test data.

- Built-in imported maintenance-free vacuum pump system for better airflow stability.

- Professional sample fixture for safer operation.

- Pneumatic clamping of the sample saves time and labor, and the clamping force is consistent.

- 7" color industrial touch screen & desktop operating system are for simple and convenient operations.

- The system has built-in calendar, multi-language switching & multi-level authority management, etc.

- Needle micro printer is connectable for the output of test results, and the results can be stored for a long time (optional).

- Standard RS232 interface facilitates the connection between the system and computer and data transmission (optional)

Test Principle

Method A:the air flow is stabilized vertically through the sample at a constant flow. Then, the pressure difference formed on both sides of the sample is measured under this condition, and air flow resistance and other parameters are calculated.

Method B:through adjustment, a constant pressure difference is formed on both sides of the sample, the air flow passing vertically through the given area of the sample in a certain time is measured, and the air permeability and other parameters are calculated.

Standard

ISO 9237, ISO 4638, ISO 5636, GB/T 10655, GB/T 5453, GB/T 4689.22, GB/T 13764, ASTM D737, TAPPI T460, JIS P8117

ApplicationsNote 1

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

Technical Specifications

Table 1: Test Parameters Note2

| Parameters/Model | TQD-G1A | |

|---|---|---|

| Differential Pressure Test Range | Pa | 0i1000 |

| Differential Pressure Resolution | Pa | 0.1 |

| Differential Pressure Accuracy | Pa | 0.25% |

| Flow Measurement Range | L/min | 0i30 |

| Flow Resolution | L/min | 0.1 |

| Flow Accuracy | L/min | 2% |

Table 2: Technical Specifications

| No. of Test Cell | 1 Cell |

|---|---|

| Specimen Size | 2 x 2 (5cm5cm) |

| Specimen Thickness | 40 Mil (1mm) |

| Test Area | 20cm2(other sizes can be customized) |

| Gas Specification | Clean Compressed Air (the air source is provided by the user) |

| Air Source Pressure | 72.5 PSI / 500kPa |

| Interface Size | I8 mm Polyurethane Pipe |

| Instrument Dimension | 12 H x 18 W x 20 D (30cm 46cm 52cm) |

| Power Supply | 120VAC10% 60Hz / 220VAC10% 50Hz (one from the two) |

| Net Weight | 55Lbs (25kg) |

Table 3: Product Configuration

| Standard Configuration | Mainframe, one set of fixtures and I8mm polyurethane pipe |

|---|---|

| Optional Parts | Computer software, air compressor |

| Notes | The compressed air inlet of this tester isI8mm polyurethane pipe (pressure79.7 PSI / 550 kPa, outlet flow > 120L/min); Air source is to be provided by the user. |

Note 1: the reference standards, test applications and product features mentioned are subject to the parameters in the "Technical Parameters".

Note 2: the parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Precision Testing According to International Standards

This tester complies with major testing standards, such as ISO 9237 and ISO 7231, assuring accurate, repeatable air permeability measurements. Designed to accommodate single specimens up to 20 x 20 cm, it provides a standardized basis for evaluating a wide range of materials, including textiles and technical fabrics. User-friendly digital controls and flexible software further enhance functionality.

Robust Design with Flexible & Safe Operation

Constructed from durable powder-coated steel, the tester features semi-automatic operation, overload protection, automatic air shutoff, and a secure safety cover. The noise level is kept below 65 dB for quiet laboratory environments, and the built-in vacuum pump ensures safe, closed-system operation. Multiple nozzle sizes and adjustable test parameters allow for broad material compatibility.

Efficient Data Handling and Advanced Customization

Digital memory storage, USB export, and an optional printer module streamline data management and reporting. Comprehensive PC software supports customized analysis and report generation. With quick response times and a wide test range (0.1-12,000 mm/s), this tester adapts easily to different production or research environments, making it an essential tool for labs and quality control departments.

FAQ's of Air Permeability Tester to test textile materials according to ISO 9237:

Q: How does the Air Permeability Tester measure air permeability in textiles?

A: The tester uses a pressure difference air flow method as outlined in ISO 9237. A specimen is secured in the test chamber, and air is drawn through it using the built-in vacuum pump. The device measures the rate at which air passes through the material, delivering digital results with high accuracy.Q: What types of materials can be tested using this equipment?

A: This tester is suitable for textiles, nonwovens, technical fabrics, paper, and similar sheet materials. Its customizable nozzle and adjustable test settings make it adaptable for a wide range of fabric densities and types.Q: When should calibration be performed on the Air Permeability Tester?

A: Calibration should be carried out at initial setup and periodically, as recommended in the instruction manual or when measurement consistency is in question. Both automatic and manual calibration options are available, and a calibration plate is included to assist with this procedure.Q: Where can test results be accessed or exported?

A: Results are viewable on the digital display and can be exported using the USB or RS232 interface. An optional printer module allows for immediate paper output. Advanced analysis and report generation are possible via the supplied PC software.Q: What is the process for conducting a test with this machine?

A: First, select the appropriate nozzle size and calibrate the machine if necessary. Place the specimen in the chamber, set test parameters on the digital control panel, and start the test. The tester automatically draws air through the material and presents results digitally after completion.Q: What are the main benefits of using this Air Permeability Tester in the lab?

A: Key benefits include precise, standards-compliant measurements, user-friendly digital operation, automatic safety features, low operating noise, and flexible data management. Its robust construction and versatile configurations support high throughput and reliable quality assurance in various laboratory settings.Q: Can the tester accommodate different specimen and nozzle sizes?

A: Yes, the device is compatible with specimen sizes of at least 20 x 20 cm and offers standard and customizable nozzle sizes (5, 10, 20, 50, 100 cm2), making it suitable for a wide array of testing requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |