Battery Separation Membrane Permeability Analyzer

50000 USD ($)/Set

Product Details:

- Resolution 0.01 m/s

- Specimen Size 25 mm (diameter)

- Max Height 960 mm

- Application Lithium battery separator permeability and performance testing

- Frequency 50 Hz

- Port Size Standard 6 mm

- Humidity 30-80% RH

- Click to View more

X

Battery Separation Membrane Permeability Analyzer Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Battery Separation Membrane Permeability Analyzer Product Specifications

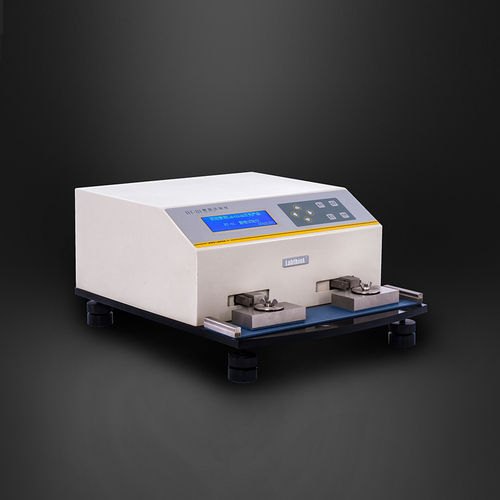

- Battery Separation Membrane Permeability Analyzer

- LCD Touch Screen

- AC 220 V, 50 Hz

- 0.01-20 m/s

- Benchtop

- High Precision, Multi-channel, Automated Testing

- 220V

- 0.5%

- Fully Automatic

- 600 mm

- Max 500 samples per day

- Room temperature, controlled (10C-40C)

- 0.1 mm/min to 500 mm/min adjustable

- Multi-position (up to 6)

- 1 s

- 0.01-20 m/s

- 0.1-0.5 MPa

- 42 kg

- 50 Hz

- 960 mm

- 25 mm (diameter)

- Lithium battery separator permeability and performance testing

- 0.01 m/s

- USB, RS232

- Laboratory/performance testing

- 30-80% RH

- PC Programming and Touch Screen

- 50 mm

- Standard 6 mm

Product Description

Product FeaturesNote1

- The instrument is controlled by computer with automatic test process

- Touch screen, easy to learn and easy to operate

- Imported high precision pressure sensors are used, which guarantees the testing accuracy and repeatability

- Imported pneumatic control system with ultra-low failure rate and extremely long service life, which guarantees the seal performance of the whole system

- Environmental temperature and humidity are monitored and recorded in real time

- 3 equivalent specimens can be tested simultaneously with the average value as test result

- Pressure curves are displayed in real time for observation and analysis of the permeation process

- The system supports unit conversion function to meet users requirements for special test

- Customizations are available for special testing function, specimen size or test pressure

Test Principle

Under certain temperature and humidity, a constant gas differential pressure is generated between the two sides of specimen. The gas transmission rate and other parameters can be obtained by analyzing and calculating pressure changes in the lower pressure side.

Test StandardNote1

ISO 5636, SJT 1071.9, GB/T 36363-2018

ApplicationsNote1

| Basic Applications |

|---|

|

Test the gas permeability of battery diaphragms, breathable films and other relative polymer products. |

Technical SpecificationsNote2

| Specifications | BTY-B3P Gas Permeability Tester |

|---|---|

| Test Range | 10 10,000 s/in2100 mL1.21KPa |

| Pressure Range | 0 20 KPa (customization is available for others) |

| High Pressure Resolution | 0.01 KPa |

| High Pressure Accuracy | 0.05 KPa |

| Low Pressure Resolution | 0.1 Pa |

| Low Pressure Accuracy | 0.3 Pa |

| Specimen Size | 12 mm12 mm |

| Test Area | 0.019 sq.in. (12.56 mm2) Customization available for other test areas |

| Number of Specimens | 3, 2 or 1 |

| Test Gas | O2, N2, CO2 and 99.9% dry gas (outside of supply scope) |

| Gas Supply Pressure | 0.6 Mpa (87 psi) |

| Port Size | I4 mm PU Tubing |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Instrument Dimension | 390 mm (L) 433 mm (W) 410 mm (H) |

| Net Weight | 27 kg |

Configurations

- Standard Configurations

- Instrument, Computer, Professional Software, I4 mm PU Tubing (2.5m)

- Note

- 1. The gas supply port of the instrument is I4 mm PU tubing;

2. Customers need to prepare gas supply.

Note 1: The described product features, applications and test standards should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Advanced Analysis for Lithium Battery Separators

This analyzer delivers precise wet and dry permeability measurements vital for assessing lithium battery separator performance. With automated testing, multi-channel analysis, and support for up to six specimens simultaneously, researchers and manufacturers benefit from thorough, efficient evaluations. High-resolution data capture and export options streamline workflow and ensure traceability.

User-Friendly Operation with Comprehensive Software

Operate the analyzer smoothly using a responsive LCD touch screen or PC programming. The included Windows-compatible software automates testing routines, manages up to 100,000 test records, and offers flexible data export in digital and graphical formats. Integrated sample preparation and fully automatic functions enhance laboratory productivity and reduce manual handling errors.

Robust Design and Compliance

Crafted from durable stainless steel, the analyzer meets IEC safety standards and maintains an ambient noise level below 60 dB. It features adjustable test speeds, controlled test environments (10C-40C), and reliable memory storage. With calibration options and precise control, it meets the demands of intensive laboratory and quality assurance applications.

FAQ's of Battery Separation Membrane Permeability Analyzer:

Q: How does the Battery Separation Membrane Permeability Analyzer measure both wet and dry permeability?

A: This analyzer utilizes dedicated testing protocols for wet and dry conditions, ensuring accurate permeability measurements. Integrated software and automated functions adapt the method according to the sample's moisture state, delivering dependable data for lithium battery separator assessments.Q: What types of data output are available, and how can results be exported?

A: The device provides both digital and graphical outputs, with data easily exportable via USB or RS232 interfaces. Users can visualize results on the LCD touch screen or export them for further analysis with Windows-compatible software.Q: When is calibration required and how is it performed on this analyzer?

A: Calibration may be necessary before initial use or after regular maintenance. The instrument offers both automatic and manual calibration modes, making routine accuracy checks straightforward and minimizing downtime.Q: Where can this analyzer be used, and what are its installation requirements?

A: Designed for laboratory settings, the analyzer's benchtop configuration fits standard lab benches. It operates on AC 220V, 50 Hz, and requires standard ambient conditions (10C-40C, 30-80% RH). Its robust design ensures stable operation in diverse research or manufacturing labs.Q: What is the process for testing multiple samples simultaneously?

A: The analyzer's multi-position sample holder accommodates up to six specimens. All samples undergo synchronized, fully automatic testing sequences, saving time and ensuring consistent test conditions for comparative analysis.Q: How is sample preparation handled with this equipment?

A: Sample preparation is fully integrated within the system. The stainless steel holders secure specimens of 25 mm diameter, streamlining the workflow and minimizing manual pre-processing steps.Q: What are the main benefits of using this analyzer for battery separator testing?

A: Benefits include high precision and resolution, automated multi-sample testing, comprehensive data management and export, adherence to safety standards, and user-friendly controls, making it ideal for rigorous battery separator performance evaluations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese