Carton Box Compression Testing Machines

50000 USD ($)/Set

Product Details:

- Test Range 0 - 60 KN

- Features Auto stop, peak hold, rapid reset, real-time digital readout

- Frequency 50 Hz

- Humidity 20% - 80% RH

- Application Compression strength testing of corrugated carton boxes

- Power Supply 220V AC, 50 Hz

- Max Height 1300 mm

- Click to View more

X

Carton Box Compression Testing Machines Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Carton Box Compression Testing Machines Product Specifications

- Compression strength testing of corrugated carton boxes

- 20% - 80% RH

- 50 Hz

- Auto stop, peak hold, rapid reset, real-time digital readout

- Digital / microprocessor based

- Up to 6000 kg

- 0 - 60 KN

- 10-300 mm/min (variable)

- 1300 mm

- 220V AC, 50 Hz

- 1300 mm

- Up to 1200 x 1200 mm

- 10C - 40C

- 220V AC

- 0 - 6000 kgf

- Industrial and packaging testing

- Approx. 450 kg

- RS 232 / USB

- 1 at a time

- Floor Mounted

- Digital LED display

- 1% of indicated value

- 0 - 1300 mm

- 1 kg

- Semi-Automatic / Fully Automatic

- Instantaneous

Product Description

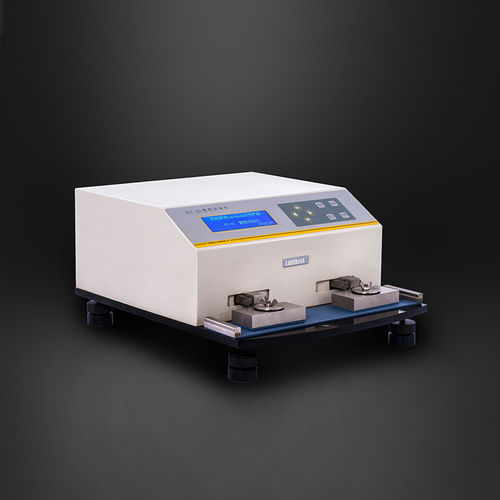

Product FeaturesNote1

- Compact and integrated design and wide range power supply ?meet the testing requirements of various applications

- Supports crushing force test, stacking test A and stacking test B

- Dynamic digital display of test force, deformation and other test data

- High performance motor and dual precision ball screws support free adjustment of test speed

- Overload protection, maximum stroke protection and error alert for safe test operation

- High end embedded computer-controlled system integrates the instrument with software requires no external computer

- Labthinks unique data security design improves the reliability of data management and test operation

- Windows-like interfaces, keyboard and mouse, which are easy to use

- Four USB ports and dual net ports for data transmission

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ASTM D642, ASTM D4169, TAPPI T804, ISO 12048, JIS Z0212, GB/T 16491, GB/T 4857.4, QB/T 1048-2004

ApplicationsNote1

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

|

Technical SpecificationsNote2

| Specifications | C611M |

|---|---|

| Load Cell Capacity | 9KN (3 pcs) |

| Accuracy | Indicated Value 1% (10% 100% of load cell capacity) 0.1% FS (0% 10% of load cell capacity) |

| Force Resolution | 1 N |

| Deformation Resolution | 0.1 mm |

| Test Speed | 0 200 mm/min (Any integer within the specified range) |

| Speed Accuracy | Indicated Value 2% |

| Stroke | 450 mm |

| Specimen Height | 0 600 mm |

| Test Space | 0.8 m (L) 0.8 m (W) 0.61 m (H) |

| Instrument Dimension | 0.85 m (L) 1.01 m (W) 1.66 m (H) |

| Power Supply | AC220V10% 50Hz / AC120V10% 60Hz |

| Net Weight | 245 kg |

Configurations

- Standard Configurations

- Instrument, Monitor, Mouse, Keyboard, 150mm Plate (1pcs)

- Optional Parts

- Auxiliary Metering Device, GMP System, DataShieldTM Note3

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Engineered for Precision and Reliability

This carton box compression tester utilizes a strain gauge-based load cell for exceptional accuracy, delivering consistent results with an error margin of just 1%. Its sturdy mild steel frame is powder coated for corrosion resistance, ensuring long-lasting operation even in demanding industrial settings. The system's digital controls and automated calibration enhance user experience, while compliance with international IS:7028 and ASTM standards assures trusted performance.

Versatile Features, Seamless Operation

Easy-to-use programming via a keypad, rapid reset, peak hold function, and optional PC connectivity give operators complete control and flexibility over every test. The universal flat plate fixture accommodates a variety of carton dimensions up to 1200 x 1200 mm, with adjustable test speed (10-300 mm/min) and stroke length (up to 1300 mm). On-site installation and training aid operators in mastering safe and efficient usage.

FAQ's of Carton Box Compression Testing Machines:

Q: How does the compression testing machine ensure high measurement accuracy?

A: The machine utilizes a high-precision strain gauge-based load cell, which delivers measurement accuracy within 1% of the indicated value. The digital microprocessor control and in-built auto calibration feature further support consistent and precise results every time.Q: What carton sizes and weights can this machine test?

A: This machine accommodates single carton specimens up to 1200 x 1200 mm in size, with a testing range up to 6000 kg (60 KN). Its universal flat plate fixture allows easy testing of a diverse range of carton box dimensions.Q: When is on-site installation and operator training offered?

A: On-site installation and detailed operator training are provided upon purchase. This ensures that users are equipped to operate the machine safely and efficiently from the outset.Q: Where should the compression tester be installed for best performance?

A: The testing machine should be installed in a test area that is clean, dust-free, and free from vibration. This ensures optimal performance and helps maintain measurement accuracy during every testing session.Q: What is the sample preparation process for carton compression testing?

A: No special sample preparation is required. Operators simply place the carton on the test platform using the universal flat plate fixture and select the desired test parameters using the programmable keypad.Q: How is test data exported and analyzed?

A: The machine is compatible with optional PC connectivity via RS232 or USB interfaces. This allows test data to be exported for detailed analysis, reporting, and record-keeping within dedicated software environments.Q: What are the main benefits of using this carton box compression testing machine?

A: Key advantages include reliable and repeatable testing, user-friendly digital controls, versatile testing capacities, comprehensive safety features, and compliance with international testing standards. Additionally, the robust build and efficient power consumption enhance overall value in industrial and packaging environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese