Leak detection for Optimal Food and Medicine Packaging

Product Details:

- Mounting Type Benchtop/Portable

- Humidity 20% 90% RH (non-condensing)

- Max Height 350 mm

- Temperature 15C 35C operating

- Test Range 1 1000 mL/min

- Measuring Range 0 999.9 mL/min

- Gas Pressure 0 600 kPa

- Click to View more

Leak detection for Optimal Food and Medicine Packaging Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Leak detection for Optimal Food and Medicine Packaging Product Specifications

- Leak Detection System

- Single/Multiple package test

- Microprocessor Based

- 1

- Digital LCD

- Leak detection for packaging

- 50 Hz

- Up to 300 mm

- 0.1 mL/min

- RS-232 / USB

- Non-destructive, Auto alarming, Built-in printer, Overload protection, Rapid analysis

- 1/4 inch NPT

- 350 mm max

- 0 600 kPa

- AC 220V 10%, 50 Hz

- 28 kg

- Up to 300 350 mm

- 2 seconds

- AC 220V, 50 Hz

- Automatic

- Food and Medicine Packaging Leak Testing

- 0.2% FS

- Benchtop/Portable

- 20% 90% RH (non-condensing)

- 0.1 50 mm/min adjustable

- 15C 35C operating

- 350 mm

- 1 1000 mL/min

- 0 999.9 mL/min

Product Description

Product FeaturesNote1

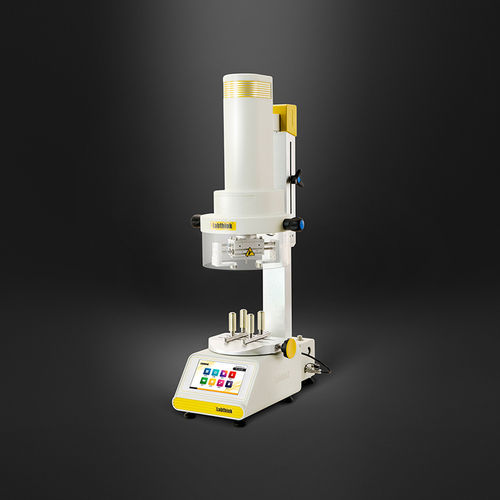

Multiple Test Modes & Automatic Testing Process

- Positive pressure method

- Multiple test modes including burst test, creep test, creep-to-failure test and pressure retaining test

- Dual test methods of restraint distension and unrestraint distension at customer's choice

- Real-time display of test curves and automatic statistics of test data

- Test range can be selected for non-standard tests

- Main components and parts are supplied by well-known global manufacturers, with guaranteed performance

Innovative Real-time Monitoring of Gas Inlet Flow

- Real-time monitoring of gas inlet flow under high pressure ensures the uniform testing condition during testing process

- High repeatability of test data

Brand New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, simplified operating interface, remote upgrade and maintenance

- Chinese and English operating interface

- Automatic data storage and power failure memory to prevent data loss

- Storage up to 1200 test records

- Multiple-level user management and login with password

- Micro-printer and USB ports for data transmission (optional)

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ISO 11607-1, ISO 11607-2, GB/T 10440, GB 18454, GB 19741, GB 17447, ASTM F1140, ASTM F2054, GB/T 17876, GB/T 10004, BB/T 0025, QB/T 1871, YBB 00252005, YBB 00162002

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

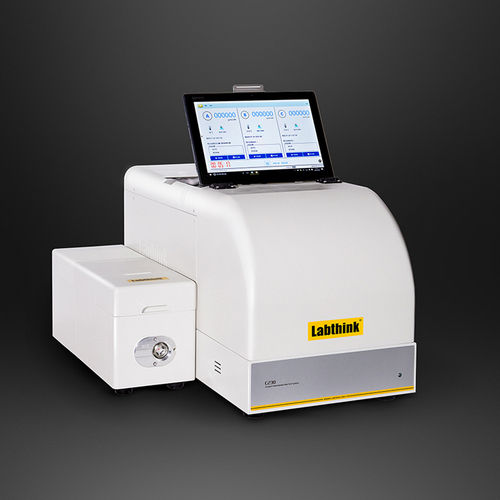

Technical SpecificationsNote2

| Specifications | C660M Leak and Seal Strength Tester |

|---|---|

| Test Range | 0 600 KPa; 0 87.0 psi (standard) |

| 0 1.6 MPa; 0 232.1 psi (optional) | |

| Resolution | 0.1 KPa / 0.01 psi |

| Pressure Accuracy | 0.25%FS |

| Gas Injection Head | I10 mm (standard) I4 mm, I1.6 mm (optional) |

| Gas Flow Rate | 0.0110L/min |

| Pressure Retaining Time | 0.1s 999999.9 s |

| Gas Supply | Air |

| Gas Supply Pressure | 0.6MPa 0.7MPa (87psi 101psi) |

| Port Size | I8 mm PU Tubing |

| Instrument Dimension | 334 mm (L) x 230 mm (W) x 200 mm (H) |

| Test Frame Size | 305 mm (L) x 356 mm (W) x 338 mm(H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 8Kg (Instrument) 16Kg (Pedestal) |

Configurations

- Standard Configurations

- Instrument, Test Frame, Sealing Gasket, 8mm PU Tubing (2m)

- Optional Parts

- Micro-printer, Professional Software, Communication Cable, Test Fixtures for Extended Applications, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument is 8 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Advanced Leak Detection for Safe Packaging

Ensure your food and medical packaging meets safety and quality standards with our state-of-the-art leak detection system. Utilizing digital vacuum control and rapid analysis, this equipment provides precise, non-destructive leak detection for a variety of materials, from PET and PVC to foil and paper multi-laminates. Meet regulatory needs with ease and deliver products with integrity to customers.

Comprehensive Data Management and Traceability

Efficiently store and track up to 100 test results, enabling easy compliance verification and data traceability. Integrated data logging and export functions simplify reporting, while a built-in printer, RS-232/USB interface, and high-resolution digital display make data handling straightforward for audit and quality assurance purposes.

Versatile and User-Friendly Operation

The system boasts programmable features, including adjustable test speeds and digital vacuum control, suitable for different package types and sizes up to 300 350 mm. Multi-language operation and automatic alarming with overload protection enhance usability, ensuring a smooth and safe testing process for operators worldwide.

FAQ's of Leak detection for Optimal Food and Medicine Packaging:

Q: How does the leak detection process work for food and medicine packaging?

A: The system employs non-destructive leak testing using air or inert gas as the test medium, applying programmable vacuum levels to detect leaks. It relies on sensitive digital sensors and rapid analysis to identify breaches in packaging without compromising product integrity.Q: What types of packaging materials are compatible with this leak detection system?

A: This system supports a wide range of materials, including PET, PVC, foil, paper, and various multi-laminate structures, commonly used in both food and pharmaceutical industries.Q: When should I perform leak testing on packaging with this system?

A: Leak tests are recommended after packaging and sealing processes, during quality assurance checks, and before shipment. Conducting routine checks ensures ongoing compliance and product safety.Q: Where is this equipment typically installed and operated?

A: This benchtop or portable system is ideal for manufacturing, quality control labs, and packaging facilities. Its compact size and universal power supply make it suitable for use in various production environments.Q: What benefits does the data logging and memory storage feature provide?

A: The built-in memory stores up to 100 test results, facilitating easy access and export of historical data for audits, compliance, and process improvements. This enhances traceability and supports robust quality control systems.Q: How do I use the different automation and safety features?

A: The device's automation functions include adjustable test speed, rapid response (2 seconds), and automatic visual and audible alarms. Overload protection and a user-friendly digital interface ensure safe and efficient operation during each testing cycle.Q: What maintenance and calibration procedures are recommended?

A: Annual calibration is advised for maintaining accuracy, with local service support available. Regular maintenance ensures the system continues to meet ISO 11607 and internal quality standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese