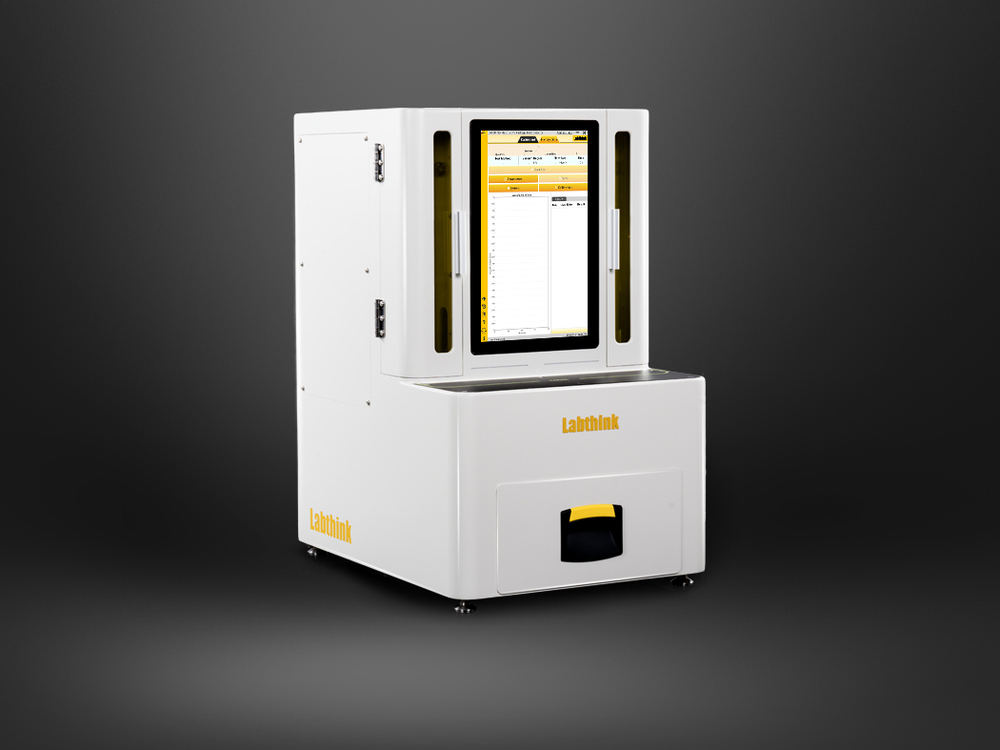

Leak Tester For Flexible Packages And Bottles

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Operating Voltage 220V AC

- Measuring Range 0-600 kPa

- Response Time 2 seconds

- Test Range 0-600 kPa

- Application Testing air-tightness/leakage of flexible packaging, pouches, and bottles

- Display Type Digital LED Display

- Number of Specimens 1 (Single sample per cycle)

- Click to View more

X

Leak Tester For Flexible Packages And Bottles Price And Quantity

- 2000.00 - 20000.00 USD ($)/Set

- 1 Set

Leak Tester For Flexible Packages And Bottles Product Specifications

- Up to 350 mm specimen height

- Adjustable test time, auto-stop, quick-release chamber, over-pressure protection

- Flexible packages/Bottles up to 200 mm width

- 6 mm OD

- 80% RH

- Table-top

- 220V AC, 50/60 Hz

- Leak Tester

- RS232

- Standard: 150 mm

- 50/60 Hz

- 0.1 kPa

- 0-0.6 MPa (adjustable)

- 15C - 40C

- 1% FS

- 1 (Single sample per cycle)

- Semi-Automatic

- 200 mm

- Laboratory/Quality Control

- Digital LED Display

- Digital/Manual

- Approx. 8 kg

- Testing air-tightness/leakage of flexible packaging, pouches, and bottles

- Variable, based on sample size

- Adjustable, up to 60 cycles/min

- 220V AC

- 0-600 kPa

- 0-600 kPa

- 2 seconds

Leak Tester For Flexible Packages And Bottles Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Product Details:

| Material | Plastic |

| Brand | Labthink |

| Display Unit | Kpa, Bar |

| Test Pressure (bar) | 0~-90kPa |

| Machine Type | Automated |

| Test Time (s) | 10S |

| Accuracy (%) | 0.1% accuracy |

| Model Number | MFY-01 |

| Weight | 48kg |

| Application | Package bags, Pouches, Bottles |

Precision Leak Testing for Quality Assurance

This leak tester provides reliable and accurate airtightness tests for flexible packages and bottles. With an adjustable chamber, cycle speed, and test parameters, the device is suited for a variety of specimen sizes up to 200 mm width and 350 mm height. Its semi-automatic controls and digital calibration ensure repeatable, high-quality results in quality control labs, manufacturing sites, or packaging research centers.

Advanced Safety and User-Friendly Operation

Built with operator safety in mind, the tester features an over-pressure cut-off, emergency stop button, and quick-release chamber. Users can set test timers up to 999 seconds and monitor progress on a digital LED display. The table-top design enables easy installation and operation, perfect for laboratory, production, or research environments.

Compliance with Industry Standards

The tester adheres strictly to ASTM D3078 and ISO 11607-1, ensuring confidence in your packaging validation process. Automatic shut-off and user-calibration simplify compliance and verification, making it a trusted component in quality assurance workflows across various packaging industries.

FAQs of Leak Tester For Flexible Packages And Bottles:

Q: How does the leak tester for flexible packages and bottles operate?

A: The device employs vacuum or pressure decay test methods using compressed air. Specimens are placed in the stainless steel test chamber, and parameters such as pressure and test time are digitally set. The system detects and displays any pressure changes to identify potential leaks.Q: What types of packages and bottles can be tested with this machine?

A: Flexible packaging, pouches, and bottles up to 200 mm width and 350 mm height can be tested. The chamber and adjustable controls accommodate single samples per cycle of varying sizes and capacities.Q: Where is this leak tester typically used?

A: It is widely utilized in laboratories, packaging quality control departments, and manufacturing environments to ensure airtightness and detect leakages in product packaging.Q: What are the main benefits of using this leak tester?

A: The tester provides precise, repeatable leakage measurements, enhances product quality assurance, meets international compliance standards, and ensures operator safety with features like over-pressure cut-off and emergency stop.Q: How can the test parameters be adjusted on this equipment?

A: Users can set the test medium pressure (0-0.6 MPa), timer (0999 seconds), test speed (up to 60 cycles/min), and select between manual or digital control modes. Test width and specimen size adjustments are available within the chambers design limits.Q: When should calibration be performed on the leak tester?

A: Routine calibration is recommended before starting a new batch or periodically based on usage frequency. The system is user-calibratable, allowing operators to ensure consistent measurement accuracy per industry standards.Q: What safety features are included to protect users during operation?

A: The leak tester is equipped with an over-pressure cut-off, an emergency stop button, and quick-release mechanisms to safeguard operators during testing. These features help prevent accidents and protect specimens in the event of unexpected pressure changes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese