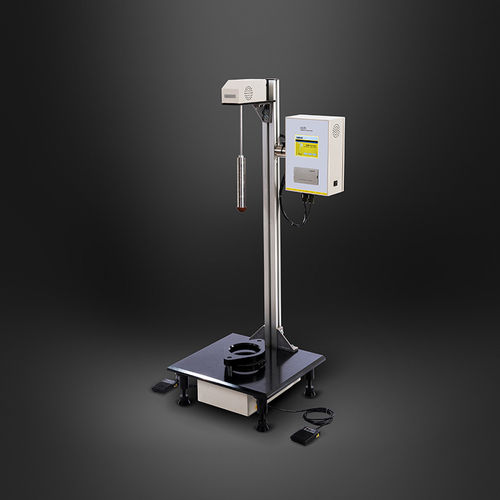

Drop Ball Impact Strength Testers

Product Details:

- Display Type Digital

- Features Safety Lock, Adjustable Height, Digital Counter

- Measuring Range 0 - 2 meters (height)

- Response Time Instantaneous

- Mounting Type Floor standing

- Automation Grade Semi-Automatic

- Number of Specimens Single specimen per test

- Click to View more

Drop Ball Impact Strength Testers Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Drop Ball Impact Strength Testers Product Specifications

- Up to 300 mm

- 220V AC

- Max. 2 kg drop ball

- Impact resistance testing of glass, plastic, or other materials

- Manual and Digital Control

- AC 220V, 50 Hz

- 10C - 40C

- Push Button/Manual Release

- Up to 200 mm x 200 mm

- 1 mm in drop height

- 0 - 1000 mm

- Adjustable (as per test standard)

- Up to 2 meters drop height

- Up to 85% RH (operational)

- Standard Drop Port - 50 mm

- 50 Hz

- 2000 mm (drop height)

- 0 - 2 meters (height)

- Safety Lock, Adjustable Height, Digital Counter

- Digital

- Lab and Industrial Testing

- Semi-Automatic

- Instantaneous

- Floor standing

- Drop Ball Impact Strength Tester

- Single specimen per test

- Approx. 55 kg

- 1 mm

Product Description

Product Features Notes1

- Menu interface, color touch screen operation, convenient and fast to set test parameters.

- Two test modes A and B are provided, and the test status is automatically judged.

- The falling dart adopts the principle of electromagnetic hanging, which can release automatically, effectively avoiding the system error caused by human factors.

- Pneumatic sample clamping, manual and pedal dual start mode, built-in observation lamp unique design; convenient, fast and accurate operation.

- Professional computer software supports the functions of multi unit display of test results, graphic display of test process, output and print function, showing the results clearly and intuitively.

- Micro printer and standard RS232 interface make the tester convenient for the external connection and data transmission between the system and the computer.

Testing Principle

At the beginning of the test, select the test method as the first procedure, estimate an initial mass and 3m value, and conduct the test. If the first sample is damaged, the weight 3m shall be used to reduce the falling mass; if the first sample is not broken, the weight 3m shall be used to increase the falling mass for test in turn. In short, the use of weights to reduce or increase the falling mass depends on whether the previous sample is damaged. After 20 samples are tested, the total number of damaged samples is calculated. If n is equal to 10, the test is completed; if n is less than 10, continue the test after supplementing samples until n is equal to 10; if n is greater than 10, continue testing after supplementing samples until the total number of undamaged samples is equal to 10. Finally, the system automatically calculates the impact results.

Reference Standard Note 1

ISO 7765-1-1988, ASTM D1709, GB/T 9639.1-2008, JIS K7124-1

Test Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

Technical Parameters Note 2

| Items | Parameters |

|---|---|

| Measuring Method | Method A, method B(optional) |

| Test Scope | Method A: 50-2000g Method B: 300-2000g |

| Weight Accuracy | +0.5% |

| Sample Clamping | Pneumatic |

| Air Source Pressure | 0.6 MPa (Prepared by user) |

| Air Connection | I 8 mm polyurethane pipe |

| Sample Size | >150 mm x 150 mm |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 70 kg |

| Dimensions | Amethod:500 mm (L) 450 mm (W) 1320 mm (H) |

| Method B: 500 mm (L) 450 mm (W) 2160 mm (H) |

Product Configuration Note 1

| Standard Configuration | A method configuration, touch screen, micro printer |

|---|---|

| Options | Method B configuration, professional software and communication cable |

| Remarks | The air source interface of the machine is I 8 mm polyurethane pipe; the air source is provided by the user |

Note 1: The product functions, reference standards and configuration information are subject to the specific marks in the "technical indicators".

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Reliable Impact Resistance Testing

Our Drop Ball Impact Strength Tester provides precise, repeatable assessments of material durability, facilitating compliance with recognized standards such as ASTM D1709 and IS 2508. This device is essential for quality assurance in industries dealing with glass, plastic, and similar materials.

Robust and User-Friendly Engineering

Constructed with durability in mind, this tester boasts a powder-coated base, stainless steel supports, and an intuitive control interface. The adjustable drop height (up to 2 meters) and safety shield ensure both versatility and operator protection during every test.

Versatile Laboratory and Industrial Applications

Designed for use in indoor laboratory settings as well as demanding industrial environments, the drop ball tester accommodates specimens up to 200 x 200 mm, providing flexible solutions for manufacturers, suppliers, and exporters across various sectors.

FAQ's of Drop Ball Impact Strength Testers:

Q: How does the Drop Ball Impact Strength Tester operate in a laboratory setting?

A: The tester allows users to secure a single specimen using adjustable clamps, set the desired drop height (up to 2 meters), and release a hardened steel ball either electromagnetically or manually. The impact strength is then measured instantly and displayed digitally with a high degree of accuracy.Q: What types of materials can be tested using this equipment?

A: This drop ball tester is designed for testing the impact resistance of glass, plastic, and other similar materials. Its versatility supports quality control and research in both industrial and laboratory environments.Q: When should the Drop Ball Impact Strength Tester be used?

A: It should be used during quality control checks, new product testing, or material research phases to verify that materials meet standardized impact resistance requirements such as ASTM D1709 and IS 2508.Q: Where should the tester be installed for optimal performance?

A: The tester is intended for use in indoor laboratory environments or industrial quality control areas, operating reliably in temperatures ranging from 10C to 40C and humidity levels up to 85% RH.Q: What is the process for conducting a test with this equipment?

A: To conduct a test, mount the specimen using adjustable clamps, set the drop height and ball diameter as per the test standard, select the release mechanism, and trigger the drop. The machine instantly measures and displays the impact result.Q: How does digital control enhance the usage of this tester?

A: Digital control provides precise drop height selection, accurate data collection, and an easy-to-read digital display, improving repeatability and reducing operator error during testing.Q: What are the key benefits of using this Drop Ball Impact Strength Tester?

A: Benefits include compliance with major standards, reliability in operation, high measurement accuracy, user safety through a dedicated shield and safety lock, and easy adaptation for various specimen sizes and materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese