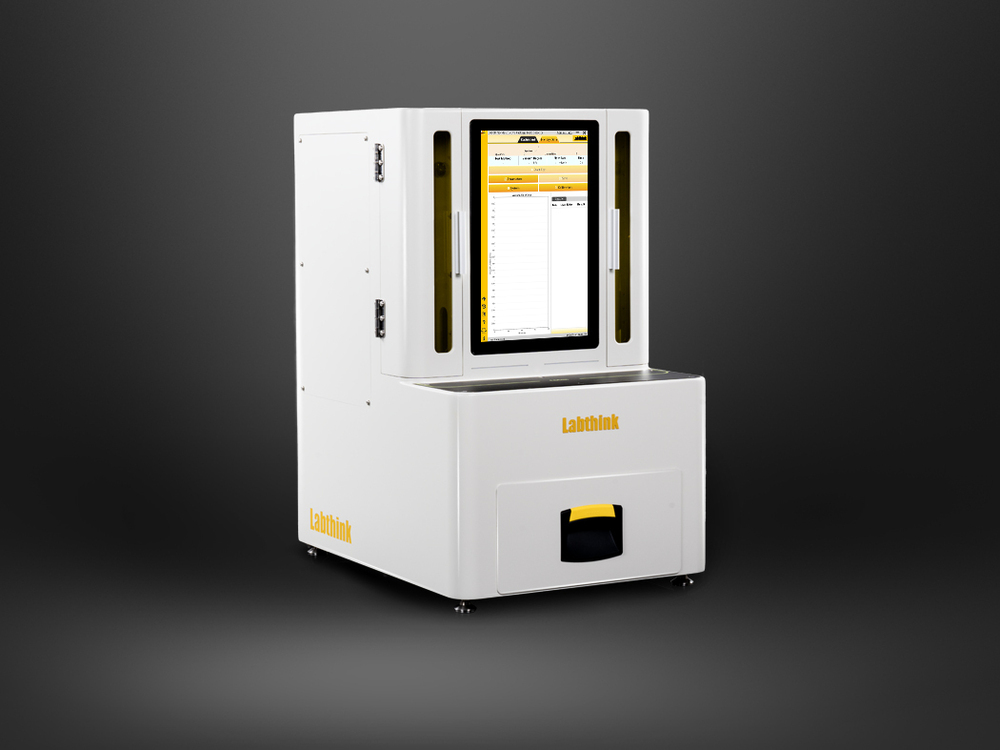

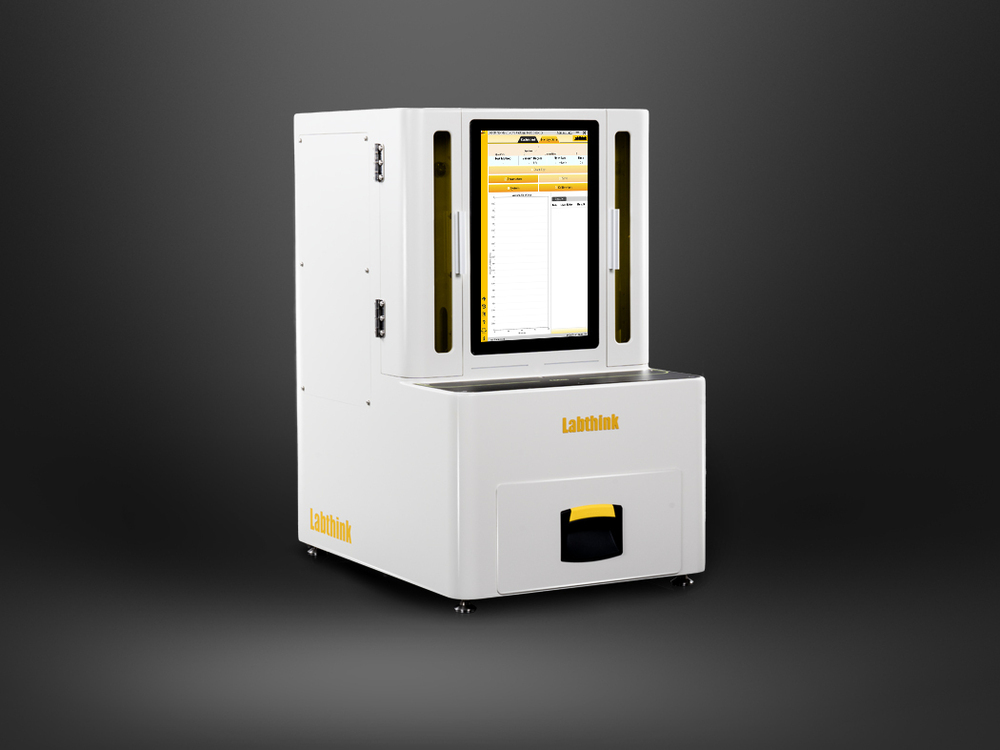

Essential Testing Instruments for Quality Control in IV Bag Manufacturing

Product Details:

- Test Range 0.1 6 bar

- Sensor Pressure sensor, Optical sensor

- Temperature Room temperature, 15-30C

- Test Material PVC, Non-PVC IV Bags

- Response Time <2 seconds

- Operating Temperature 15C to 35C

- Display LCD digital panel

- Click to View more

Essential Testing Instruments for Quality Control in IV Bag Manufacturing Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Essential Testing Instruments for Quality Control in IV Bag Manufacturing Product Specifications

- Pressure sensor, Optical sensor

- PVC, Non-PVC IV Bags

- Room temperature, 15-30C

- 220V AC, 50/60 Hz

- Standard IV port sizes (customizable)

- Quality testing of IV bags

- 300 mm x 400 mm

- 0.1 6 bar

- Stainless Steel

- 1-5 per cycle

- 220V/110V AC

- 30-80% RH

- <2 seconds

- 18 kg

- LCD digital panel

- 15C to 35C

- Adjustable, up to 6 bar

- Single or Multiple IV bags

- Air, Water

- Automatic/Manual

- Leak Tester, Burst Tester, Tensile Tester, Seal Strength Tester, Visual Inspection System

- 0.2% F.S.

Product Description

Product FeaturesNote1

Multiple Test Modes & Intelligent Statistics of Qualified Specimens

- Negative pressure method

- Multiple test modes including standard, multi-grade vacuum and methylthionine chloride mode

- Automatic test with traditional methylthionine chloride

- Vacuum degree, test time and infiltration time can be adjusted and test parameters can be saved automatically so that the tests with same test parameters can be started quickly

- Automatic constant pressure compensation ensures that the tests can be performed under preset vacuum conditions

- Real-time display of test curves, easy to observe the test results

- Automatic statistics of qualified specimens

- Main components and parts are supplied by well-known global manufacturers, with guaranteed performance

Brand New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, simplified operating interface, remote upgrade and maintenance

- Chinese and English operating interface

- Measurement unit conversion

- Automatic data storage and power failure memory to prevent data loss

- Storage up to 1200 test records (standard mode)

- Multiple-level user management and login with password

- Micro-printer and USB ports for data transmission (optional)

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test Principle

Firstly submerge the specimen in the water in the vacuum chamber, and then evacuate the vacuum chamber to form differential pressure between the inside and outside of specimen. The seal property can be obtained by observing the steady progression of bubbles from the specimen or observing how the specimen expands and restores to its original shape after vacuum release.

Test StandardNote1

ASTM D3078, GB/T 15171

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

Technical Specifications

| Specifications | C660B |

|---|---|

| Vacuum Degree | 0 -90 KPa/ 0 -13 psi |

| Accuracy | 0.25% FS |

| Resolution | 0.1 KPa / 0.01 psi |

| Vacuum Chamber Effective Sizes |

I270 mm x 210 mm (H) (standard) |

| I360 mm x 585 mm (H) (optional) | |

| I460 mm x 330 mm (H) (optional) | |

| Note: customization is available for other sizes | |

| Gas Supply | Air (outside of supply scope) |

| Gas Supply Pressure | 0.5 MPa 0.7 Mpa (73psi 101psi) |

| Instrument Dimension | 334 mm (L) x 230 mm (W) x 170 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | Instrument: 6.5 kg Standard Vacuum Chamber: 9kg |

Configurations

- Standard Configurations

- Instrument, Standard Vacuum Chamber (I270 mm x 210 mm), I6 PU Tubing (1m)

- Optional Parts

- Micro Printer, Professional Software, Customized Vacuum Chamber, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument isI6 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Ensuring Reliable Quality Compliance

These instruments are engineered to help manufacturers meet rigorous international standards such as ISO 8536 and CE. With built-in alarms for failures and high memory capacity, you can trust the integrity and traceability of your testing process, ensuring every IV bag meets safety and regulatory demands.

Advanced Technology & User-Friendly Interfaces

Utilizing adjustable gas pressure up to 6 bar and supporting both automatic and manual modes, these testers accommodate single or multiple specimen sizes. The systems feature rapid response time (<2 seconds), LCD digital display panels, and both touch screen and keypad options for streamlined operation and data visibility.

Durability and Environmental Resistance for Demanding Environments

Crafted from corrosion and chemical resistant stainless steel, these instruments are suitable for challenging laboratory or manufacturing environments. The robust housing secures longevity and continuous reliable operation, ensuring consistent performance regardless of working conditions.

FAQ's of Essential Testing Instruments for Quality Control in IV Bag Manufacturing:

Q: How do these testing instruments ensure compliance with ISO 8536 and CE standards in IV bag manufacturing?

A: The instruments integrate standardized testing protocols and measurement accuracy (0.2% F.S.), supporting ISO 8536 and CE certification requirements. Integrated software guides operators through appropriate test procedures, automating record storage and analysis for complete audit trails.Q: What types of tests can be performed with these devices and what IV bag materials are supported?

A: These systems are capable of conducting leak, burst, tensile, seal strength, and visual inspections on both PVC and Non-PVC IV bags. The flexible test range (0.1 - 6 bar) and specimen capacity (1-5 per cycle) make them suitable for varied production needs.Q: When and how is calibration handled for these testing instruments?

A: All instruments are factory calibrated to ensure accuracy and regulatory compliance out of the box. Manual recalibration is possible whenever required, maintaining long-term measurement reliability and consistent product quality.Q: Where are these instruments typically installed, and what are their space requirements?

A: Designed as bench-top units, these devices fit well in laboratory or on-site quality control areas, requiring a pedestal size of 300 mm x 400 mm and overall dimensions of 560 mm x 480 mm x 530 mm. Their compact footprint facilitates integration into existing workflows.Q: What process is followed for testing multiple IV bags, and how are results recorded?

A: Users can test between 1 and 5 IV bags per cycle. The integrated software collects and stores up to 5000 individual test records, with data output available via USB or data logger. Alarms notify operators immediately of any test failures, supporting prompt quality management.Q: How do audio/visual alarms enhance the testing process?

A: Audio and visual alerts promptly inform operators of any deviation or failure during testing. This immediate feedback allows for timely intervention, minimizing defective batch risks and ensuring only compliant IV bags proceed in the manufacturing process.Q: What are the main benefits of using these instruments in IV bag manufacturing and exporting?

A: By ensuring rapid, accurate, and documented testing with environmental resistance and high throughput, these instruments enhance product safety, regulatory compliance, and operational efficiency-critical advantages for manufacturers, exporters, and suppliers in global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leak and Integrity Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese