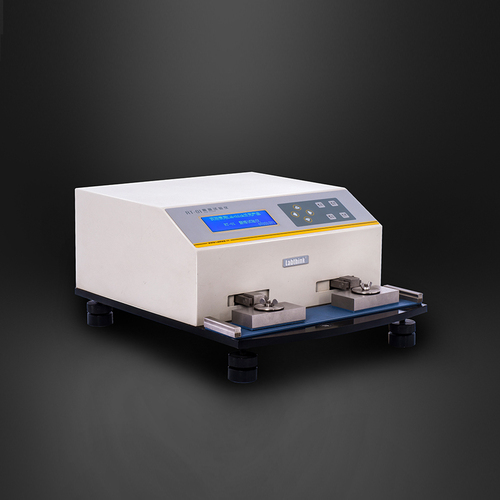

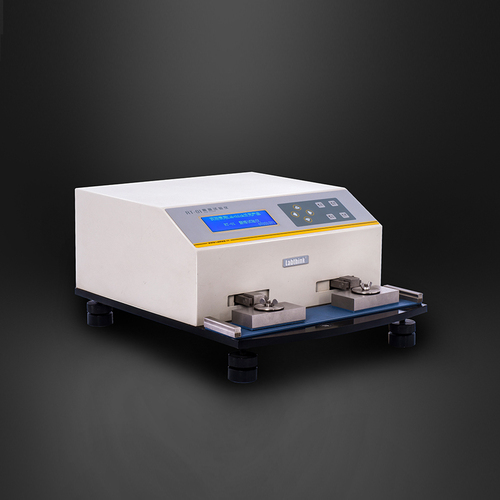

RT-01 Printed Materials Coating Payers Abrasion Resistance Tester

50000 USD ($)/Set

Product Details:

- Number of Specimens 12

- Response Time Immediate

- Temperature 1535C

- Automation Grade Semi-automatic

- Measuring Range 01000 cycles

- Operating Voltage 220V AC

- Mounting Type Benchtop

- Click to View more

X

RT-01 Printed Materials Coating Payers Abrasion Resistance Tester Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

RT-01 Printed Materials Coating Payers Abrasion Resistance Tester Product Specifications

- 60 cycles/min

- Easy operation, precise abrasion measurement

- Printed materials, film, coating paper abrasion resistance test

- Laboratory testing of paper and film coatings

- 4080% RH

- 1 cycle

- 180 mm

- 1 cycle

- 220V/50Hz

- 50 Hz

- 23050 mm

- 12 mm

- 0.50.7 MPa

- Manual, digital

- Abrasion Resistance Tester

- 6 mm

- 01000 cycles

- Abrasion resistance of printed coatings

- Digital display

- 220V AC

- Digital Control

- Benchtop

- Semi-automatic

- 1535C

- Immediate

- 12

- 80 mm

- 28 kg

- 01000 cycles

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Precision Testing for Coating Durability

Designed specifically for laboratories, the RT-01 tester ensures exact measurements of abrasion resistance in printed coatings and films. Its programmable cycles and digital control enable repeatable results for quality assurance specialists and researchers alike, supporting consistent product development and evaluation.

Safe, Reliable, and Easy to Operate

Safety is prioritized in the RT-01 with built-in overload and short-circuit protection, while the digital display and easy-to-use interface make it simple to program and monitor tests. Its durable stainless steel surface and robust export packaging provide long-lasting, dependable performance for manufacturers and laboratory environments.

FAQ's of RT-01 Printed Materials Coating Payers Abrasion Resistance Tester:

Q: How is the RT-01 Abrasion Resistance Tester operated during a typical test?

A: The RT-01 is semi-automatic and programmed via its digital control panel to set test cycles (0-1,000 cycles). Simply mount your sample in the holder, adjust your desired settings, and use the included polyurethane brush to ensure consistent abrasion. Results are displayed instantly on the digital screen.Q: What types of materials can be tested with this device?

A: This tester is suitable for measuring the abrasion resistance of a variety of printed materials, coated papers, and films. Its adjustable specimen holder accommodates samples sized up to 23050 mm.Q: When should laboratories consider using the RT-01 tester?

A: Laboratories and manufacturers should use the RT-01 whenever product development or quality control requires objective assessment of coating layer durability on printed substrates, films, or coating papers.Q: Where is this tester best utilized?

A: The RT-01 is engineered for benchtop placement in laboratory environments. Its compact footprint (410380280 mm) and export-grade wooden case make it suitable for both domestic and international facilities.Q: What is the testing process with the RT-01 Abrasion Resistance Tester?

A: Begin by preparing the specimen (1-2 per test), placing it in the holder, and setting the desired cycles and speed (60 cycles/min, 12 mm stroke). Start the machine; the polyurethane brush delivers abrasion and the digital system records the cycle count-results are immediately displayed.Q: How does the RT-01 benefit manufacturers or researchers?

A: The programmable test cycles and 1 cycle accuracy provide repeatable, precise measurement of material abrasion resistance. Fast response and compliance with international standards allow manufacturers to validate product durability efficiently and reliably.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ink Rub Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese