Pressure and Parallelism Control in Mechanical Thickness Testers Ensuring Materials Quality

Product Details:

- Response Time <1 sec

- Gas Pressure 0.6 MPa

- Application Materials Quality Inspection

- Humidity 80% RH

- Specimen Size 50 x 50 mm

- Accuracy 0.001 mm

- Automation Grade Semi-Automatic

- Click to View more

Pressure and Parallelism Control in Mechanical Thickness Testers Ensuring Materials Quality Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Pressure and Parallelism Control in Mechanical Thickness Testers Ensuring Materials Quality Product Specifications

- 0.5 mm/s

- 6 mm

- 50/60 Hz

- AC 220V/50Hz

- 10C - 40C

- 0-10 mm

- Digital

- Mechanical Thickness Tester

- Pressure and Parallelism Control, Stable Measurement, Robust Construction

- Thickness Testing of Rubber, Plastic, Film, and Paper

- 0.001 mm

- 1

- RS232C

- 0 - 10 mm

- Standard Shore A

- 65 kg

- 220V

- Bench Top

- 50 x 50 mm

- 80% RH

- 75 mm

- Materials Quality Inspection

- 0.6 MPa

- 500 N

- <1 sec

- Automatic / Manual

- 110 mm

- 10 mm

- Semi-Automatic

- 0.001 mm

Product Description

Features

Professional

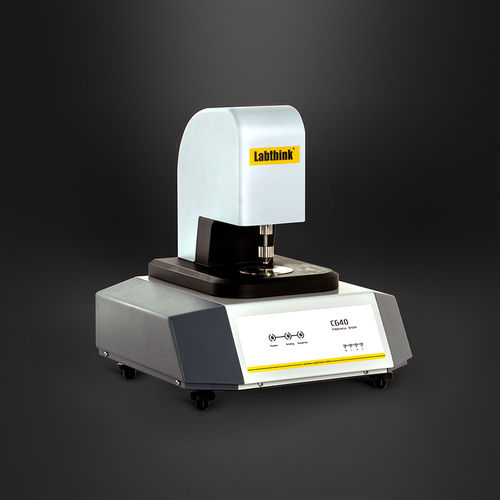

With innovative research and development, Labthink C640 Thickness Tester uses high precision displacement sensor, supported by scientific structure and professional control technology, which makes C640 greatly improved in stability, repeatabilityNote1 and accuracy.

- The instrument conforms to standards for mechanical contact method. The pressure foot can be lifted and lowered automatically, which can minimize the errors caused by human operation.

- Contacting time and test speed can be set as required. Customization is available for multiple contact areas and pressures, which can meet the requirements for various test conditions.

- Manual and automatic test modes can be selected by the users

- Calibration of multiple points can improve the linearity of the whole test range, which ensures the accuracy of measured results.

- Standard gauge block is available for fast calibration

High Efficiency

The instrument is featured with high efficiency and automatic design of structure, which minimize the human operation in measuring process. Intelligent controlling and data processing functions make it easy and reliable for test operation and data processing.

- Parameter program function enables the user to save all test parameters in a file so that those parameters can be applied directly for the same tests next time, which can help the user save time and minimize the error when inputting parameters manually.

- Test results include maximum value, minimum value, average value and standard variation, which can be displayed to the user directly.

- Result comparison function can help the user in evaluation of results.

- Auto sampling function (optional), feeding space, feeding speed, measure points can be set as required, which ensures the accuracy of multiple successive points measurement.

Intelligent

The instrument is embedded with Labthinks latest operating software, which is featured with user-friendly interface, intelligent data processing, strict user management and secure data storage. It also supports Labthink exclusive DataShieldTM (Optional) which provides the users with safe and reliable management of test data and test reports.

- Test data can be displayed in various forms including curves and data list

- Test data will be saved and encrypted in a unique way so that all the test information will be saved securely and reliably and protected from being tampered

- Various forms of test data can be searched, exported and printed out

Note: The described features should be in line with Table 1: Test Parameters.

Note1: The Repeatability refers to the repeatability within the test range.

Test Principle

The pre-conditioned specimen is placed on a flat test plane, the pressure foot which is paralleled to the test plane will drop down on the upper surface of the specimen with certain pressure applied on. The displacement sensor with the pressure foot will detect the space between the upper and lower surface of the specimen, which is the thickness of the specimen.

Test Standards

ISO 4593, ISO 534, ASTM D6988, ASTM F2251, GB/T 6672, GB/T 451.3, TAPPI T411, BS 2782-6, DIN 53370, ISO 3034, ISO 12625-3, ISO 5084, ASTM D374, ASTM D1777, ASTM D3652, GB/T 6547, GB/T 24218.2, FEFCO No 3, EN 1942, JIS K6250, JIS K6783, JIS Z1702

Note: The described test standards should be in line with Table 1: Test Parameters.

Applications

| Basic Applications |

|---|

|

|

| Extended Applications |

|

|

|

|

|

Technical Specifications

Table 1: Test Parameters Note1

| Parameter Model | C640M | C640H | |

|---|---|---|---|

| Test Range (Standard) | mm | 0 2 | 0 2 |

| Resolution | m | 0.1 | 0.1 |

| RepeatabilityNote3 | m | 0.8 | 0.4 |

| Test Range (Optional 1) | mm | 0 6 | 0 6 |

| Test Range (Optional 2) | mm | 0 12 | 0 12 |

| Feeding Space | mm | 0 1000 (Adjustable) | |

| Feeding Speed | mm/s | 1.5 80 (Adjustable) | |

| Additional Functions | Auto Sampler | Optional | Optional |

| DataShieldTM Note2 |

Optional | Optional | |

Table 2: Technical Specifications

| Measuring Method | Mechanical Contact Method |

|---|---|

| Test Pressure & Contact AreaNote3 | Film: 17.51 KPa, 50 mm2 |

| Paper: 1001 KPa (Standard) / 501kPa (Optional), 200mm2 | |

| Instrument Dimension | 370 mm (L) x 350 mm (W) x 410 mm (H) |

| Net Weight | 26kg |

Note1: The parameters in the table are measured by professional operator in Labthink laboratory according to relative requirements for laboratory standard conditions. For extended applications, customization is available to meet the special testing requirements.

Note2: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be purchase as required.

Note3: Test pressure and contact area can be selected for paper or film. There are two options for test pressure for paper, i.e. 100kPa (standard) and 50kPa(optional). For other test pressure and contact area or curved pressure foot, customizations are available.

Advanced Pressure & Parallelism Control

Achieve reliable thickness measurements with our tester's pressure and parallelism control, maintaining consistent contact between the specimen and polished chrome plate. The stable measuring environment ensures precise data for every test-critical for quality inspection of various thin materials like film, paper, and rubber.

User-Friendly Data Management

Streamline your testing process by storing up to 1000 test results. The built-in USB port and RS232C interface allow convenient export of measurement records to your PC for comprehensive documentation and reporting. This helps ensure reproducibility and traceability throughout your operation.

Safety and Compliance First

Engineered for secure usage, the tester features overload protection and an emergency stop mechanism. Constructed from RoHS-compliant stainless steel and aluminum alloy, it aligns with global safety and environmental standards, ensuring both product and operator safety.

FAQ's of Pressure and Parallelism Control in Mechanical Thickness Testers Ensuring Materials Quality:

Q: How does the Mechanical Thickness Tester ensure precise thickness measurements?

A: The tester incorporates advanced pressure and parallelism control to maintain uniform contact with each specimen, supported by a polished chrome contact surface. This design, paired with a digital display of 0.001 mm resolution and 0.001 mm accuracy, guarantees reliable and consistent thickness readings for materials like rubber, plastic, film, and paper.Q: What is the process for storing and exporting test results?

A: Up to 1000 test results can be stored within the device. Test data is easily exported to a PC via the USB port or RS232C interface, allowing for seamless documentation, analysis, and reporting in quality management applications.Q: When should I calibrate the tester, and what options are available?

A: Calibration should be conducted regularly or whenever measurement accuracy is in question. The tester supports both automatic and manual calibration modes, ensuring optimal accuracy and meeting specific operational needs.Q: Where can this tester be effectively utilized?

A: This Mechanical Thickness Tester is ideal for laboratory, manufacturing, and quality control environments-anywhere precision measurement of thin materials like film, paper, rubber, or plastic is required. Its bench-top, semi-automatic design makes it suitable for exporters, manufacturers, and suppliers.Q: What safety features are included in the equipment?

A: Safety is enhanced by overload protection mechanisms and an emergency stop function, safeguarding both the device and operator during use. LED status indicators also provide clear updates on the machine's operational state.Q: How does the device accommodate multilingual usage?

A: The tester offers multi-language support, including English and Chinese, making it accessible to a broad range of global users and operators.Q: What are the main benefits of using this thickness tester?

A: Users benefit from high measurement accuracy, large data storage, robust construction, enhanced safety features, easy data transfer, and multi-language support, all of which contribute to efficient and reliable materials quality inspection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese