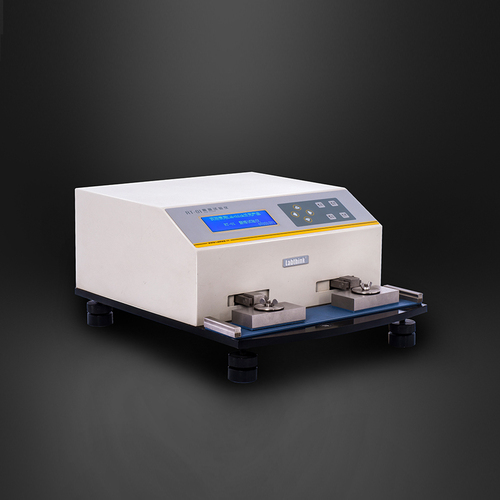

Reciprocal movement tester of print wears

50000 USD ($)/Set

Product Details:

- Number of Specimens 16

- Mounting Type Bench-top

- Features Programmable cycle count, auto stop, multi-specimen testing

- Hardness Standard shore D

- Power Supply AC 220V, 50Hz

- Response Time Instantaneous

- Test Range 0200,000 cycles

- Click to View more

X

Reciprocal movement tester of print wears Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Reciprocal movement tester of print wears Product Specifications

- 0200,000 cycles

- Instantaneous

- 10100 mm (adjustable)

- 40%85% RH

- 50 Hz

- 0.50.6 MPa

- Semi-automatic

- Testing print wear and abrasion resistance on printed materials

- 1 cycle

- 1%

- 16

- Bench-top

- 100 mm

- Laboratory/Quality Control

- Programmable cycle count, auto stop, multi-specimen testing

- 55 kg

- AC 220V, 50Hz

- Standard shore D

- Digital Control

- LCD Digital

- Print Wear Test Machine

- 15C40C

- 6 positions

- 400 mm

- 6 mm

- 0100% wear

- 1060 cycles/min (adjustable)

- 50150 mm (max)

- USB/RS232

- 220V

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

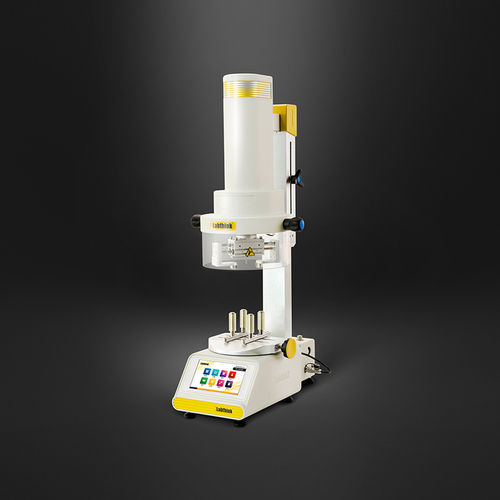

Programmable and Precise Test Performance

The reciprocal movement tester offers adjustable test speeds, stroke lengths, and programmable timers to ensure detailed and repeatable abrasion testing. Its precision linear actuator delivers consistent motions, which, combined with a high-accuracy (1%) measuring system, enables reliable assessment of print wear under various laboratory conditions.

Enhanced Safety and User-Friendly Controls

Safety is a priority with built-in overload protection, an emergency stop feature, and compliance with international standards. Digital controls and an intuitive LCD facilitate easy customization of test parameters, while instant response time helps streamline quality control routines.

Rugged Build for Demanding Environments

Constructed from stainless steel and alloy, this machine offers minimal vibration and stable performance. A small footprint (500350 mm) makes it suitable for most laboratory benches, allowing seamless integration into print material testing workflows.

FAQ's of Reciprocal movement tester of print wears:

Q: How does the Reciprocal Movement Tester process abrasion tests on print wear samples?

A: The tester mounts up to six printed specimens and subjects them to reciprocating linear motion within a programmable stroke and cycle range. Users can set wet or dry abrasion conditions, monitor the progression in real time via the LCD, and receive precise wear measurements for each cycle.Q: What types of printed materials can be evaluated using this equipment?

A: It is suitable for nearly all print substrates, accommodating specimen sizes up to 50 150 mm, making it ideal for evaluating print quality and durability across various materials, including paper, plastics, and coated stocks.Q: When should this machine be calibrated, and what calibration methods are available?

A: Calibration should be performed before critical tests and periodically as part of laboratory quality protocols. The tester offers both manual and automatic calibration options to ensure ongoing accuracy to ISO/ASTM standards.Q: Where can this print wear tester be safely operated?

A: Designed for indoor laboratory and controlled quality control environments, its moderate noise level (<65 dB) and ambient operating conditions (15-40C, 40-85% RH) suit most industrial and research settings.Q: What is the typical process for setting up a test on this machine?

A: Users mount specimens, configure stroke length and test cycles via the digital interface, and select wet or dry abrasion mode. Gas pressure and power requirements are checked before initiating the programmable test sequence.Q: How does automated safety enhance laboratory operation?

A: Overload protection and an emergency stop button protect both users and samples, while compliance with strict ISO/ASTM safety standards reduces risk and ensures dependable results.Q: What are the key benefits of using this tester in print material quality control?

A: The tester delivers accurate, repeatable wear assessments, supports multiple specimens, and features rapid cycle programming. This enhances testing efficiency, supports compliance, and fosters continuous product improvement.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese